In industries that use CNC machining, there can be many team members that contribute to the production of the final product. The process starts with the designer creating the CAD model that is then sent to the programmer for CAM programming. Once the program is complete, the code is sent to the operator to set up and run the CNC machine.

Efficient communication is key to optimal production. If the machine is not producing parts, it is still considered downtime, even during the period when the programmer and operator are tying up the machine with a test of the code. With the levels of communication between all the parties involved, there are many opportunities for information to be lost or misinterpreted.

Within CAMWorks, there are three main options that can help solve the communication issues that arise between the programming office and the shop floor.

CAMWorks Machine Simulation

Machine simulation is a common practice in Digital Twin technology and in CAM it can be used to confirm an error free program. Issues such as the pre-position being called out by the program leading to a crash can be checked virtually in the simulation and easily corrected in the software before it becomes an even greater issue on the actual machine.

Setup Sheets

Setup sheets can be easily generated by CAMWorks with all the information needed by the Setup Technician to set up the tools to be used in the program. Operational data and tooling parameters can be conveyed to the shop floor in a simple easy to read document.

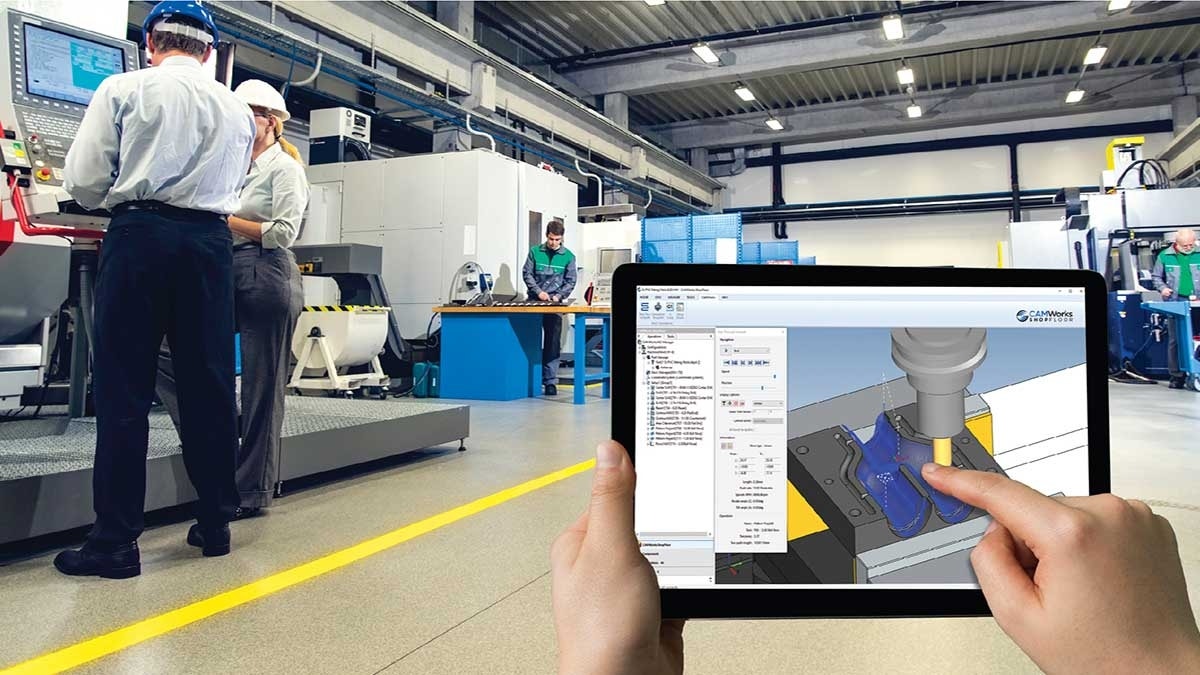

CAMWorks ShopFloor

CAMWorks ShopFloor allows shop personnel to review the CAM files without requiring a license of CAMWorks. A dry run of the part can be performed virtually, leaving the CNC free to continue production. The operator can gain an understanding of the programmer’s intent without having to leave the machine.

Watch the Webinar Now

In this webinar, we cover these three solutions to the common machine shop communications issues in more depth.

If you have any questions about CAMWorks or are interested in learning more about how you can improve your shop floor’s efficiency, contact us at Hawk Ridge Systems and our experts will be happy to help!