Design changes WILL happen, it’s just a matter of time. As an engineer, wouldn’t you rather spend your time coming up with new ideas for the next generation of your design rather than trying to hunt through data to find what you need?

We’ve all been through situations where the wrong revision of a design was sent out for production, or maybe that CAD file was moved to another file location, and now you can’t find it. You can probably think of your own examples that are similar but may have had to do with a need for more powerful product data management (PDM) tools.

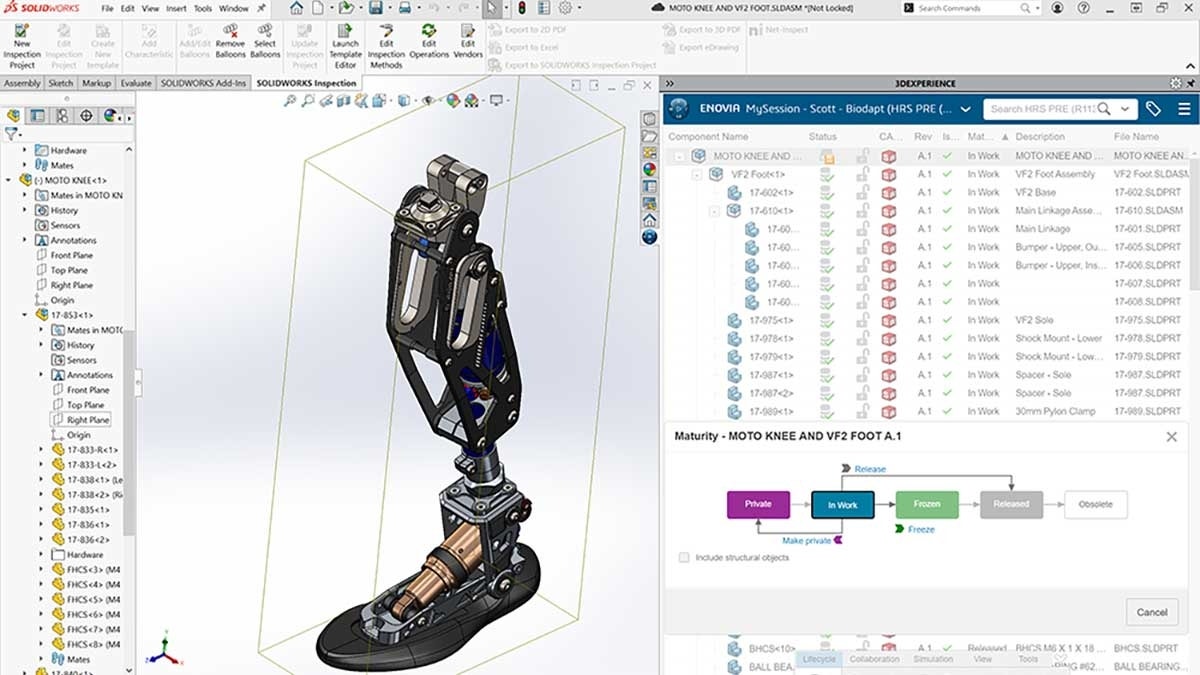

SOLIDWORKS PDM can help any organization focus their attention on designing better products instead of manually managing their files or the changes that need to happen with them. Here, we’ll focus on a few key aspects of SOLIDWORKS PDM that help you manage your files and change processes with ease.

File References

A parametric CAD system like SOLIDWORKS will use some form of file reference system to organize the parts and subassembly files that belong to the top-level design. If you’ve ever renamed or moved a SOLIDWORKS file, you know just how critical it is to maintain those references to keep your assembly file working correctly.

With SOLIDWORKS PDM, you don’t have to worry about using any special tools, workarounds, or tribal knowledge to properly manage your references. Your database will constantly keep track of all design files, while allowing them to be renamed or moved directly from Windows Explorer. The beauty of a PDM system, though, is you can choose which individuals have permissions to do this. No more issues with people accidentally moving of files when they shouldn’t have had that ability in the first place.

Workflows

When a design is released for manufacturing, you probably have a process that you follow, right? Maybe it involves sending emails with attachments or messaging your coworkers to review what you’ve done and passing this information along to production.

The problem with a manual process, outside of a data management system, is that it’s difficult to control the flow of that data and make sure that everyone is using the correct data.

Workflows in SOLIDWORKS PDM allow you to incorporate product release and approval processes directly with your CAD files. Simply changing the state of a file will allow users to be notified of next steps that need to be taken.

Revision Scheme

Manually inputting revision information into files can be cumbersome. Many times, this involves creating copies of those files and, if you’re not using a PDM system, that can be risky.

You’ll never have to duplicate files again with SOLIDWORKS PDM. Work with your original, native files throughout their entire lifecycle, and allow the system to automatically apply revision information to the files you’re managing. Manual renaming of files with “-REV C” or “-1, -2”, etc. is a thing of the past. Reduce the number of files you are responsible for and reclaim your design time in SOLIDWORKS.

File Output

Once your design has been revised, reviewed, and released for production, you might have other file formats that need to be consumed. This could include PDFs of your drawing that get sent to manufacturing, STEP files for CNC programming, DXFs for laser cutting, etc. If you’ve ever spent more time than you’d like creating these finalized documents or “release packages,” SOLIDWORKS PDM can help.

By implementing task automation, SOLIDWORKS PDM can automatically convert your CAD files to the alternate formats you need, with minimal input from your users. Send the files through your approval workflow, and the system will take care of the rest.

Watch Webinar Now

If you’d like to see more about how these tools work, be sure to check out our on-demand webinar, “Standardizing Change Management with SOLIDWORKS PDM.” In this webinar, we take a deeper dive into how all the concepts above can simplify your design processes, and help you reclaim your valuable time.

If you’d like to learn more about SOLIDWORKS PDM or other data management solutions, contact us at Hawk Ridge Systems and we would be happy to help you! Thanks for reading and watching our webinar.