Many worthwhile endeavors motivate us to continue to improve, and it’s paramount in the world of manufacturing, where competition can be global. It’s healthy to constantly review your capabilities or analyze your shop’s limits to understand your strengths and weaknesses.

Ultimately, you learn more about how you can improve your business based on new evolving needs. One area to consider is when to upgrade your CAM software.

2 Reasons to Upgrade Your CAM Module

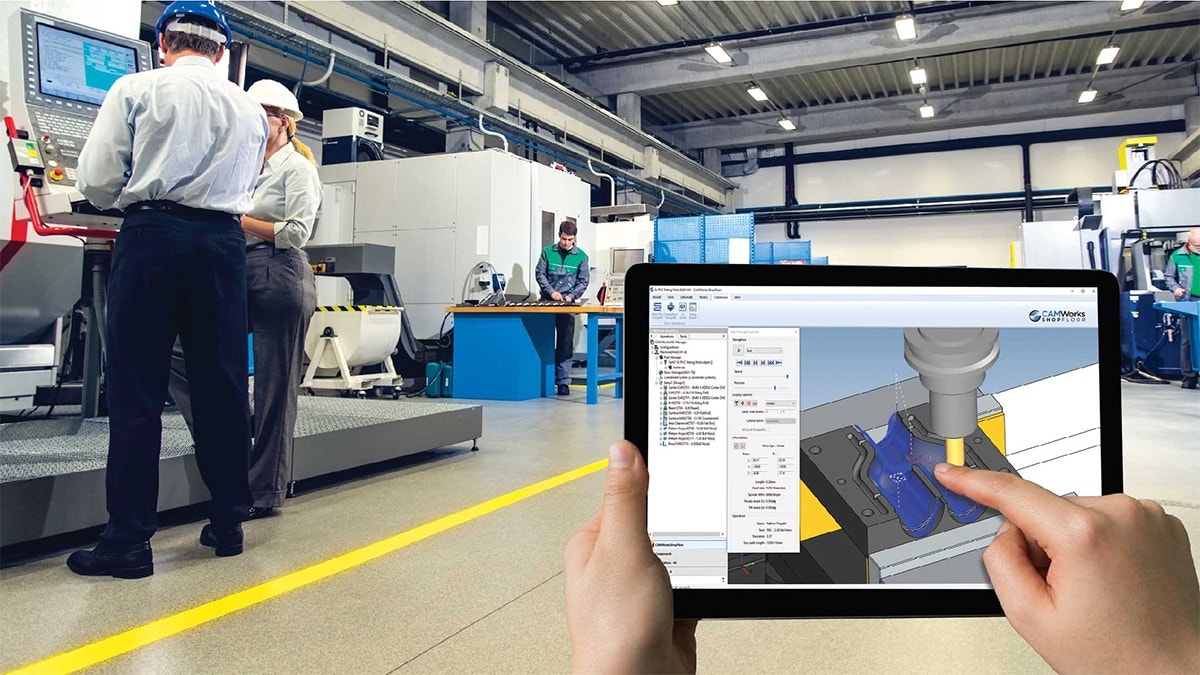

SOLIDWORKS CAM and CAMWorks are powerful CAM software that can assist with programming many types of machines, so it’s important to understand the best option for your workflow.

1. Your Current CAM Has Limitations

The most common reason people upgrade their CAM is because of limitations. You want your CAM module to work in SOLIDWORKS 3D, either roughing or finishing your part.

Most people decide workarounds are better than upgrading their software. But it’s best to determine the level of work you want to get into and purchase the appropriate CAM module rather than finding workarounds to achieve the same result but with considerably more effort.

2. You Have an Increase in CNC Machine Complexity

Another reason for upgrading your CAM is to match your shop’s increase in CNC machine complexity. Most modern multi-axis machines have so many uses and capacities that choosing your CAM module can feel overly complex in itself.

There is a tendency to “overbuy” your CAM, which means you purchase a module with more functions than you actually would use in your own workflow.

Learn About Which CAM Modules Are Best for You

In this webinar, you will learn how to decide between all the powerful CAM modules available from Hawk Ridge Systems, which modules apply to which types of applications, and which option best suits your workflow.

If you have any questions or need help determining which module is appropriate for your shop, contact us at Hawk Ridge Systems.