Product Lifecycle Management (PLM) has increased in demand as more industries are requiring software that coordinates all the details of their products. We’re sure you’ve seen and heard over the last few years that software is eating the world and PLM software is at the table as well. Having a PLM system allows an organization to manage resources for a project utilizing project visibility, processes, tasks and timelines.

SOLIDWORKS Manage adds to capabilities found in most PLM systems by including the connection to an existing SOLIDWORKS PDM Professional vault, allowing project bill of materials (BOM) to be brought in from the existing SOLIDWORKS mechanical BOM and modified to capture additional non-modeled items such as electrical components, tooling and assembly requirements, and documentation. Let’s take a closer look at how SOLIDWORKS Manage can be a solution for PLM needs.

Solution for Project Management

Using SOLIDWORKS Manage, organizations can plan each stage of their projects, from concept to shipping. When a new project comes in, a project template can be brought in to produce a Gannt chart with a breakdown of each step of the project along with its progress. From here, project specific modifications can be added, resources can be assigned, and tasks can be generated at each step to provide a project status overview.

Changes to the project can be applied and easily inserted into the project plan and SOLIDWORKS Manage will automatically adjust the schedule according to additional stages. Additional tasks can be issued as well, and users can track time on each stage. When users complete their work, the project progress is automatically updated, giving a good overview of the status of a project and what is required for completion.

With SOLIDWORKS Manage building upon an existing PDM system, Project Management becomes easier because product design is incorporated into the existing system. Tasks can be assigned for part creation, change orders or analysis and CAD users can perform the necessary action through the SOLIDWORKS Manage interface or with SOLIDWORKS PDM via the Manage Add-in.

Solution for Process and Item Management

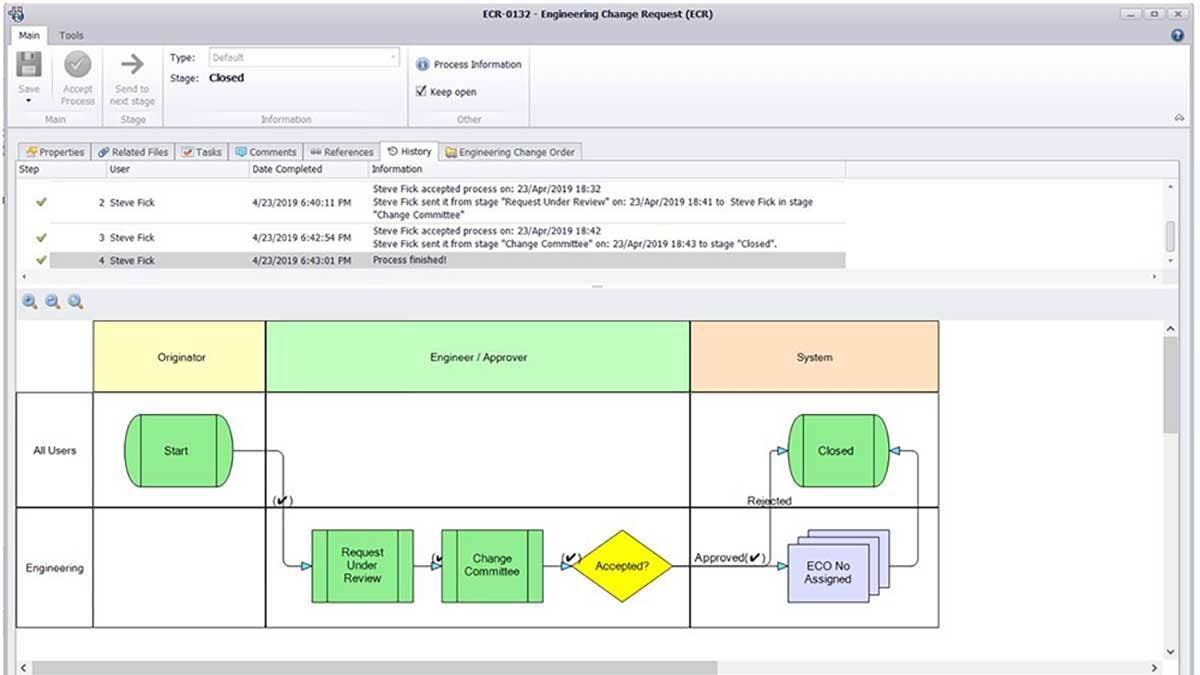

When changes are required within a project, SOLIDWORKS Manage provides highly configurable process workflows. Just like SOLIDWORKS PDM, tracking changes and the revision history of the project is made easy. With SOLIDWORKS Manage, no Excel or siloed project management applications are needed. Records are created for each process, and references can be attached to the process such as redlines, Change Order documentation, or the CAD files themselves.

Throughout the different stages of the process, actions are required by specific users, many of which tasks cannot be efficiently captured and managed in a file and/or by commonly overused Excel documents. As mentioned in our recent blog, “Solving the Top 4 Challenges in PDM With SOLIDWORKS Manage,” one of the key limitations of PDM Professional stems from the paradigm that it is a superb file management system. In other words, why rely on a file to capture all the components of your process? Yes, there are workarounds with virtual documents etc., but SOLIDWORKS Manage is the optimal tool for wholistic process management. In SOLIDWORKS Manage, tasks can be generated, sub-processes can be created, and the proper people can be notified of needed actions.

Processes work very similarly to SOLIDWORKS PDM workflows; however, a process is generated for a record, and items can be added to the record from multiple sources. In the case of an Engineering Change Order (ECO), the ECO record can be created, then affected files can be referenced. The process goes through a workflow, and during the review stage, a specified team can confirm that the changes are required and proceed. Approvers can be set by the stage or added dynamically as the record proceeds through the process.

Want to kick-off a process or case directly from Outlook or save emails to records? SOLIDWORKS Manage makes this automation simple. For integration with PDM, when the process stage advances, related files can be moved within the PDM workflow to a working stage while the ECO waits in an implementation phase. Upon completion of the changes, SOLIDWORKS Manage can be used to review the design work to ensure the ECO can be fully approved and released.

Solution for Visibility and Analysis

With the entirety of the lifecycle controlled by SOLIDWORKS Manage, reports can be generated based on crucial project information, such as time tracking, and shipping BOM instructions. These reports can be configured to publish automatically or on demand. Knowing the time and resources being put into a product’s lifecycle can help find bottlenecks and issues in the manufacturing process, and corrective action can be taken to lower costs, improve quality and decrease manufacturing time.

Dashboards can be used to get a quick view of the key information of a project and its components. The elements of a dashboard can be customized to provide real time data on performance indicators, combining data from various sources into an easy to manage format.

How does SOLIDWORKS Manage Compare to other PLM options?

Full disclosure, Hawk Ridge Systems is one of the world’s largest SOLIDWORKS resellers and over the last twenty years we have done over 1,300 SOLIDWORKS data management implementations, so yes, we are a little biased. That said, the feedback we have consistently heard from our customers moving away from other PLM systems is that they were a bear to implement and administer. Integrating to ERP/MRP and even making simple configuration changes to workflows, user groups, permissions, etc. was cost prohibitive and the system needed a full team to maintain. As a result, the PLM tools ultimately would end up in a state where they did everything they need, but nothing they want, even though they were paying for all the software. Some deployments never even made it to production environments due to missed expectations and a failed implementation or POC – a great five-year vision but no year one reality.

From a licensing and implementation cost standpoint, SOLIDWORKS Manage tends to be on-par with, or significantly less than, comparable PLM systems. This delta is widened if the concurrent user count, implementation, integration and training scope of work is similar. The process management capabilities in SOLIDWORKS Manage are on par or greater given the depth of functionality and the project management capabilities are far superior. The consensus around the project management capabilities included is that they would typically get put on the shelf on day one and just go with using Microsoft Project instead. Since SOLIDWORKS Manage is in the SOLIDWORKS ecosystem, it follows the same release schedule as all other SOLIDWORKS applications, so no need for a third-party plugin and being held back for months, even years for that provider to release updated support of your latest SOLIDWORKS CAD release.

SOLIDWORKS Manage was added to the portfolio in January 2018 as the result of a joint venture with RevZone. It was a great tool but struggled with market awareness in a crowded field of large marketing budgets. Let us just say, you would not see an advertisement for it during the Super Bowl. The main objective of the partnership was to directly comport to the PDM Professional customer feedback over the years which suggested a strong demand for more capability around Project, Process, Item and BOM Management plus Dashboard & Reporting. Today, RevZone continues their R&D efforts in cooperation with SOLIDWORKS R&D through this joint venture.

If you are already an existing SOLIDWORKS PDM Professional user, you only pay the difference between SOLIDWORKS Manage licensing and SOLIDWORKS PDM Professional, which saves you about half the cost of the SOLIDWORKS Manage perpetual licensing software. No migration is needed either if you are upgrading from SOLIDWORKS PDM Professional. All SOLIDWORKS Manage licenses, like SOLIDWORKS PDM Professional, are global floating licenses which can save you quite a bit versus the traditional named-user only seats. Like PDM Professional, the application can be deployed on-premise or on cloud/IaaS. In the last couple of years many of our customers have opted for the latter, leveraging the world’s two most widely utilized cloud infrastructure providers: Microsoft Azure and AWS EC2.

As stated, our implementation is typically less expensive than most traditional PLM systems, yet more expensive than the “free” options which “only take minutes to setup,” but we are candid with you on the specifics of your implementation and training statement of work to set realistic expectations. What it looks like in a full work breakdown structure and timeline. What is on you and IT vs. where we do the heavy lifting as our core competency. If you have ever been involved in either end of the PLM implementation spectrum, you should be very pleased with how thorough our scoping and implementation process is relative to the amount of time and monetary investment needed. In orders of a rough magnitude, a SOLIDWORKS Manage project is at least double the complexity of a SOLIDWORKS PDM Professional project, so give yourself one to three months to be safe. So, well over “minutes” and substantially less than nine months to a year.

Is SOLIDWORKS Manage the Right Solution?

SOLIDWORKS Manage is a great solution for those looking for a single software solution that keeps track of all the data from different sources in your company regarding product development and simplifies it for easy consumption. By consolidating the data all into one location, it allows managers to make critical product decisions quickly and efficiently, resulting in lower costs and faster time to market. SOLIDWORKS Manage truly shines when you incorporate it with SOLIDWORKS PDM, combining projects, processes, tasks, and the physical files all in one ecosystem, creating a single source for data tracking for the entirety of a project’s lifecycle.

Why Hawk Ridge Systems?

Given our wealth of experience and deep bench of dedicated data management solution architects, sales specialists, and support technicians, you are partnering with a team that has seen it all and can provide optimal resources to support you during implementation and beyond. We support the lion’s share of SOLIDWORKS’ largest data management customers, so you can be provided with the confidence that we are likely not going to approach unchartered waters. We’ve setup complex enterprise deployments consistent of over a half dozen replication sites across multiple countries and hundreds of users, yet many of our customer’s only have 5 to 15 users. That said, yes, of course will still talk to you even if you have a requirement of less than 25 PLM users. Given we support PDM/PLM users across the globe with 22 offices in North America, Hawk Ridge Systems has a 12-hour support window (5PM to 5PM PST). This means you get directly to the right subject matter expert with a 98% connection rate and our support response times are often less than one-minute. We’ve been in the industry for close to a combined 20-years and worked for several other companies, small to Fortune 200s, all with customer support as their mission, and we can tell you Hawk Ridge Systems really practices what it preaches around customer service. This commitment to provide exceptional support to our customers (and employees) is the major reason why a large amount of us have been with Hawk Ridge Systems for a long time, including many senior solution architects on our team for over a decade. Hawk Ridge Systems is also a very stable company in an environment that lately has been anything but. This is critical as you determine who the right partner is to support your organizations data management platform over the next five to 10 years.

If you have any questions on SOLIDWORKS data management tools, feel free to contact us at Hawk Ridge Systems team. Thanks for reading!

This blog is coauthored with Noah Krygier. Noah has been in the hardware & software sales industry for 17 years. He’s been with Hawk Ridge Systems for over 5 years as an account manager covering the Pacific Northwest out of our Oregon office and then for the last three years as Product Sales Manager of our Enterprise Solutions team. He’s passionate about working with our customers and their new product introductions and staying involved in as many data management projects as possible. When he’s not working, he’s spending time with his family, camping, watching sci-fi flicks and exploring the outdoors on anything with wheels.