Just like with any manufacturing process, there is no 3D printing material that fits the requirements for every single application. For example, some parts will require extreme strength to succeed in their application while others need high heat resistance. Further still, some parts may require the ability to bend and flex while maintaining chemical resistance to accomplish their intended function. To help with applications such as these, Markforged has added the new Smooth TPU 95A material to their Digital Forge. In this post, we will look at some properties of this new material and how you can use it to further take control of your supply chain.

Smooth TPU 95A Properties

TPU stands for Thermoplastic Polyurethane, which is a category of plastics that is primarily known to have good flexibility and elasticity. Traditionally, material like this can be difficult to print on an extrusion-based printing system precisely because of how flexible it is.

In filament form, TPU takes little force to completely bend out of shape.

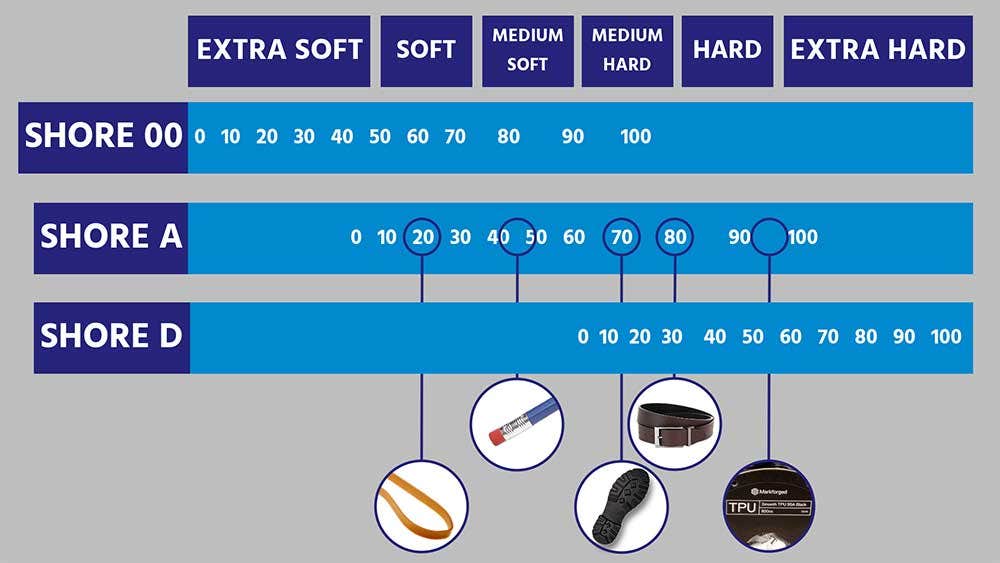

That being the case, the Markforged Smooth TPU material prints better than other elastomers due to where it sits on the Durometer Shore Hardness Scale. The Shore scales are typically used as a common point of reference for elastomers and cover a wide range of material hardness. The Shore 00 scale usually encompasses materials that are very elastic while the Shore A and D scales cover materials that increase in hardness until reaching the level of something like a bone at a hardness of 90D.

The shore scales cover a wide range of material hardness until reaching extremely rigid materials at the end of Shore D.

As implied by the material name, Smooth TPU 95A sits at a Shore hardness of 95 on the A scale. This puts it above items such as a rubber band at 20A, a pencil eraser at 45A, and a shoe sole at 70A. A common example of a 95A hardness material is a shopping cart wheel.

Smooth TPU 95A sits near the top of the Shore A hardness scale.

3D Printing with Smooth TPU 95A: Applications and Advantages

Even though a 95A hardness material is usually rigid, additive manufacturing allows for the unique possibility of creating parts with partially hollow interiors. In turn, this can result in parts that mimic the characteristics of softer materials. By quickly adjusting the infill percentage of a TPU part using the Markforged Eiger slicing software, users can manufacture parts that are more flexible than a traditionally manufactured 95A hardness elastomer.

Markforged 3D printers can create parts that would be impossible to manufacture with traditional methods.

Because of this ability to print lower density interiors, Smooth TPU 95A is great for a wide range of applications requiring elastic and resistant parts. This includes items such as protective coverings or cases, custom gaskets, and even serpentine or drive belts.

Smooth TPU 95A parts exhibit great flexibility and surface finish.

Smooth TPU 95A is a great material for protective cases, gaskets, and drive belts.

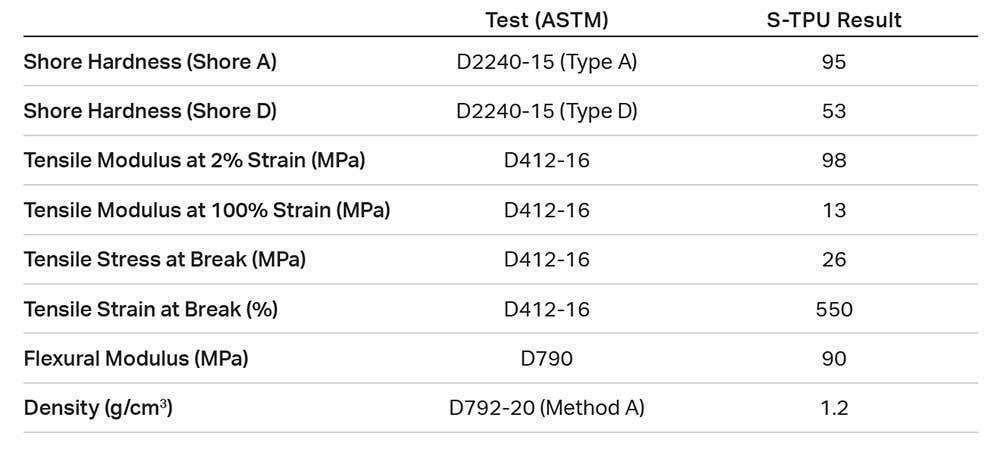

Beyond being flexible, Markforged Smooth TPU is also an exceptionally durable material. In testing, Markforged found that parts printed with Smooth TPU could experience a 550% elongation to break before failure. This means that it would take a lot of effort to tear these parts as they can stretch five times their length without failing.

Testing data for Smooth TPU 95A, courtesy of Markforged.

Thanks for reading everyone! We are excited to have an elastomer available on Markforged printers and we cannot wait to see what you produce. Smooth TPU 95A is currently available for any Gen 2 Onyx Pro or Mark Two and is coming soon to industrial systems.

Check out our site for more information on Markforged 3D printers, and if you have any questions, be sure to contact us at Hawk Ridge Systems today.