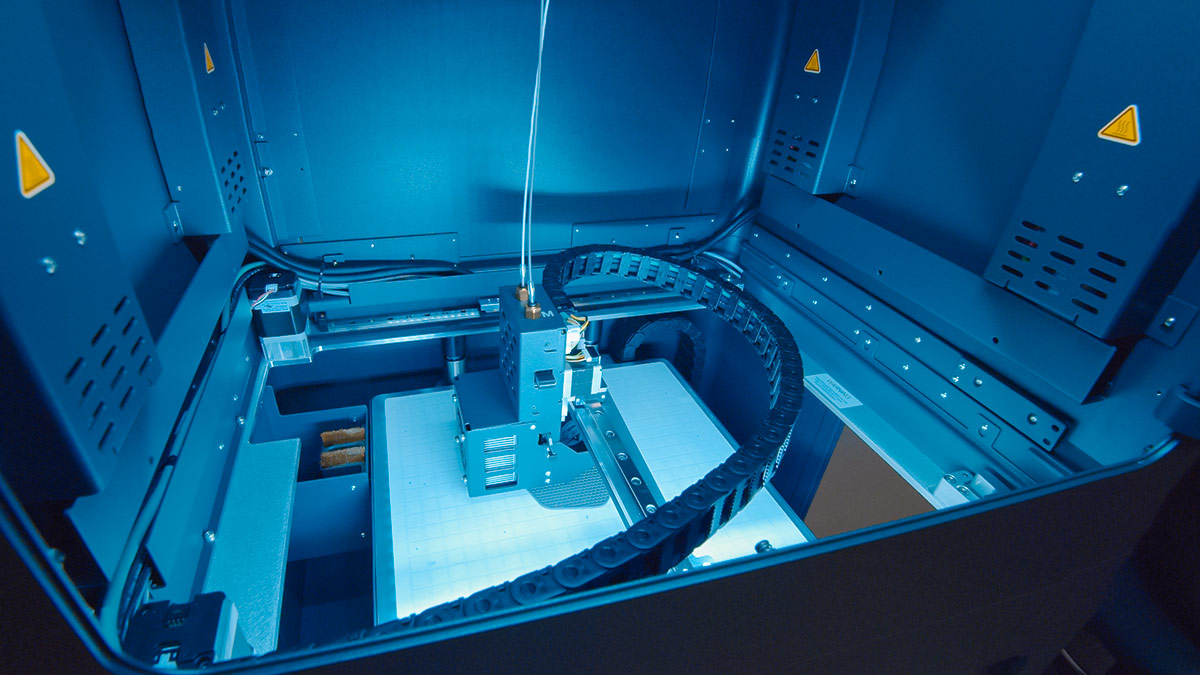

Markforged Desktop Printers

Get Pricing Sent to You Today

While you are waiting, check out our Resource Center or read our Blog!

Strong, Versatile 3D Printed Parts. Small Printer Footprint.

The Markforged Desktop Series of 3D Printers allows you to bring your designs to life through additive manufacturing without the large footprint of traditional industrial printers.

Using professional Fused Filament Fabrication (FFF) technology, the Onyx One gives you high-quality, chopped carbon fiber parts, quickly. If you need something even stronger, step up to the Onyx Pro or Mark 2. These 3D printers are unique in their ability to embed continuous fibers into the part during the printing process for reinforcement to increase strength and stiffness, sometimes even rivaling aluminum.

Markforged combines durable, precision hardware, quality materials, and smart software and technology to give you high-quality, reliable parts at the touch of a button.

-

Onyx

Nylon chopped carbon fiber mixed material that is stronger than standard nylon with a black color and excellent surface finish.

-

Nylon

Flexible, soft material with a less abrasive finish, ideal for non-marring work holding applications. Material also can be reinforced with fiber for high-strength applications. Nylon is white in color.

-

Fiberglass

The most affordable fiber that will reinforce your parts and still achieve significant rigidity improvements.

-

HSHT Fiberglass

A very strong fiber that has the highest heat deflection temperature of any Markforged fiber, HSHT Fiberglass is perfect for high-temperature applications.

-

Carbon Fiber

Create parts stronger than aluminum utilizing the highest tensile strength fiber that Markforged has to offer.

-

Kevlar

Impact-resistant fiber with higher elongation to break, perfect for applications with sudden high loads.

-

Continuous Fiber Reinforcement (CFR)

Create parts with aluminum-like strength by reinforcing plastic parts with continuous fibers.

-

Eiger Software

Cloud-based slicing software for sending and managing print jobs for all Markforged printing systems. The software is free to use; sign up and try it today!

-

Offline Eiger

This offline, subscription-based version of Eiger software is designed for companies that require higher security measures.

-

Eiger FleetThis software is geared toward those with multiple printers or those looking to have more customization with Eiger software. Features include: open APIs for integrating Markforged printers with existing enterprise software solutions such as CRM systems custom analytics tighter control of user groups and teams

Technical Specifications

|

Features

|

Onyx One

|

Onyx Pro

|

Mark Two

|

|---|---|---|---|

|

Build volume

|

12.60” x 5.20” x 6.06” (X,Y,Z) 320mm x 132mm x154mm

|

12.60” x 5.20” x 6.06” (X,Y,Z) 320mm x 132mm x154mm

|

12.60” x 5.20” x 6.06” (X,Y,Z) 320mm x 132mm x154mm

|

|

Layer thicknesses

|

100 micron, 125 micron, 200 micron

|

100 micron, 125 micron, 200 micron

|

100 micron, 125 micron, 200 micron

|

|

Model base materials available

|

Onyx

|

Onyx

|

Onyx, Nylon

|

|

Reinforcement fiber materials available

|

None

|

Fiberglass

|

Fiberglass, HSHT Fiberglass, Carbon Fiber, Kevlar

|

|

Overall size of machine

|

23” x 13” x 14” (X,Y,Z) 584mm x 330mm x 355mm

|

23” x 13” x 14” (X,Y,Z) 584mm x 330mm x 355mm

|

23” x 13” x 14” (X,Y,Z) 584mm x 330mm x 355mm

|

|

Weight of the machine

|

35lbs / 16kg

|

35lbs / 16kg

|

35lbs / 16kg

|

|

Power requirements

|

100-240VAC, 150W (2A peak)

|

100-240VAC, 150W (2A peak)

|

100-240VAC, 150W (2A peak)

|

Revolutionizing Dragsters With Markforged

In the high-speed, high-stakes world of jet engine drag racing, manufacturing quality parts is a matter of life and death. Just ask Josette Roach, one of only five female jet dragster drivers in the entire world.

Josette Roach and Brian Tocci of Larsen Motorsports saw the need to create a custom steering wheel for Josette’s jet car that would fit her hands exactly. Enter Markforged, and our Simulation software, which allowed the team at Larsen to build this part with top-end accuracy.

Services & Customer Benefits

Technical Support

Unmatched Training

Hawk Ridge offers complete self-paced training programs for the Markforged line of 3D printers. Learn printer operations, how-tos, and best practices when it’s convenient for you.

Professional Services

Frequently Asked Questions

Fiber infill can help create a stronger and stiffer part while maintaining advantages of additive manufactured parts such as light weight parts.

No, there are no special requirements for ventilation of Markforged composite 3D printers.

No, there is no need for a heated bed or chamber to build quality parts. The parts are built in a natural room environment within an enclosed frame.

Isotropic fiber will improve the overall stiffness in the XY plane while concentric placement will improve the strength of the walls in the Z Axis.

Yes, there are three sparse fill patterns including triangular, hexagonal and rectangular, along with solid.

Periodically, you will need to change the tubes and the print nozzles for each material. The printer will keep track of this and remind you when you need to perform the maintenance. Additionally, you will need to keep the machine clean, tension the belts when prompted, clean and re-glue the bed after each print, and re-level the bed every few prints.

Yes, you will need to buy material from Markforged. The material is developed, tested, and manufactured by Markforged to create a complete system of tested materials and machines to ensure your parts meet the quality and performance standards required by a professional 3D printer.

What software do I need to build a part using a Markforged printer?

The support material is the same material used for the model. It is created automatically by the slicing software and easily removed by hand or with a small needle nose pliers.

+/- 250microns x/y ; +/- 1 layer thickness in Z

Markforged Resources

See It Firsthand: The New Markforged FX20

Watch Live Stream

An Overview of Markforged Materials

Watch Video

Choosing Your Markforged 3D Printer

Download Guide