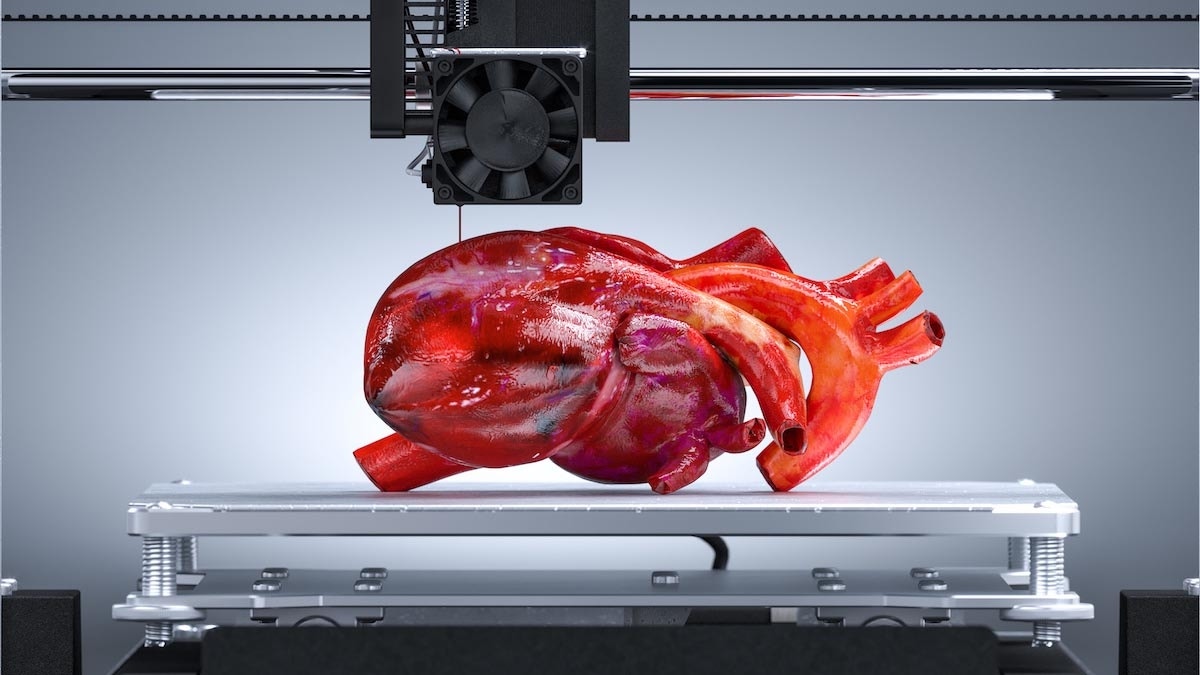

3D printed hearts, livers, kidneys and more. Sounds like something out of a sci-fi story, but it’s real, and it’s happening aboard the ISS.

Biomedical 3D Printing in Space

In November of 2022, researchers continued 3D printing of human tissue (bioprinting) tests on the International Space Station (ISS). Printing in space eliminates the issue of tissue collapse due to gravity, making it ideal for bioprinting. While some projects focus on organ tissue printing like heart, liver, and kidney tissue, others focus on tissues like human cartilage. One important research project currently on-going aboard the ISS is the 3D printing of the meniscus – a dainty, yet extremely important piece of cartilage between the bones of the knees. Almost one million meniscus tear repair surgeries are conducted in the United States every year, a surgery that can cost anywhere between $5,000 and $30,000 dollars for patients. The research conducted on the ISS for biomedical printing could have huge implications for people on Earth, reducing costs to patients, and, perhaps, even speeding up operating room time.

Why space though? The limitations of printing soft tissues on Earth

Printing soft tissues, like cartilage and blood vessels, has been a major challenge in regenerative medicine. Gravity on Earth causes these tissues to collapse under their own weight. To tackle this obstacle, researchers have turned to the ISS, where gravity is absent.

The absence of gravity in space eliminates the need for scaffolding to support printed tissues, allowing them to maintain their shape without collapsing. This opens up new possibilities for printing complex soft tissues and even organs that could potentially be transplanted into patients on Earth. The BFF’s counterpart, the Advanced Space Experiment Processor (ADSEP), plays a crucial role in culturing and conditioning the printed cells, enabling them to strengthen and hold their shape.

In-space bioprinting offers several advantages over its terrestrial counterparts. Firstly, the ability to print true tissue-like structures in a gravity-free environment allows for larger and more intricate prints. This enables researchers to create tissue models for drug discovery, reducing the reliance on animal testing and opening new avenues for therapeutic development. Moreover, the potential for vascularization of printed tissues could pave the way for more advanced models and therapies.

Introducing the BioFabrication Facility (BFF)

The BioFabrication Facility (BFF), developed by Redwire Space, is a 3D bioprinter specifically designed for printing human tissues in space. This state-of-the-art device is capable of using a combination of adult human cells and proteins, known as bioinks, to create intricate tissue structures. The BFF’s upgraded version, set to be launched to the ISS on Northrop Grumman’s 18th Commercial Resupply Services (NG-18) mission, offers improved temperature control and new camera views for better print control.

In May of 2023, astronauts went up to the ISS for eight days and conducted around twenty different experiments, some of which used the BFF.

The most recent research project for the BFF involves phase II of creating a human meniscus, aimed at helping benefit service members who have had knee injuries. BFF-Meniscus-2 seeks to print and culture a meniscus aboard the International Space Station using the BioFabrication Facility. Upon return to Earth, findings from this research can help improve our understanding of bioprinting in space.

Addressing the organ shortage and implications for drug discovery

While astronauts can easily create tools and parts onboard, additive manufacturing in zero-gravity environments has much broader implications. The shortage of organs for transplantation is a critical issue in healthcare. In-space bioprinting has the potential to accelerate the production of transplantable organs.

If the BFF and ADSEP system can discover methods to mass-produce organs, it would be a game-changer for patients in need of life-saving transplants. Current research includes printing and processing cardiac tissue onboard the ISS aimed at ultimately alleviating the organ shortage on Earth. Another current research project, led by Axiom and the Wake Forest Insititute of Regenerative Medicine investigates the printing of liver and kidney tissue.

In addition to tissue transplantation, in-space bioprinting holds promise for drug discovery. By printing organoids, miniature functional organs, researchers can test the efficacy of new therapeutics in a more accurate and ethically sound manner. This could revolutionize the pharmaceutical industry and accelerate the development of life-saving medications.

Challenges and opportunities in biomedical printing

While in-space bioprinting shows immense potential, there are still challenges to overcome. Ensuring the viability and safety of the printed tissues during the return journey to Earth is a critical aspect that requires further research. Additionally, the scalability and cost-effectiveness of the technology need to be addressed to make it accessible to a wider audience.

Looking ahead, additive manufacturing in space is incredibly promising. Further advancements in technology, combined with ongoing research and collaboration, could unlock new frontiers in regenerative medicine and transform the way we approach healthcare.

What’s next for the future of biomedical printing in aerospace?

The success of in-space bioprinting relies on collaboration between various stakeholders. Public-private partnerships, like the one between Redwire Space and the ISS National Laboratory, provide the necessary resources and expertise to push the boundaries of medical device manufacturing in space. By pooling together knowledge and resources, we can accelerate the development of this revolutionary technology.

The era of additive manufacturing in space has the potential to revolutionize the field of medical device manufacturing. In-space bioprinting offers a unique solution to the challenges faced on Earth, allowing for the creation of complex tissues and organs that could transform the lives of patients. As researchers continue to explore the possibilities of printing human tissues in a gravity-free environment, we are on the brink of a new frontier in regenerative medicine.

Learn how Hawk Ridge Systems can help with your medical device manufacturing projects

Hawk Ridge offers several products and services to help with MedTech additive manufacturing. From circuit board design, mechanical design, design cycle management, and rapid prototyping, we’ve got you covered.

Check out the following to learn more:

HP 3D printers for MedTech

Formlabs 3D printers for MedTech

Markforged 3D printers for MedTech

SOLIDWORKS Flow Sim

SOLIDWORKS PDM

Meetup with Hawk Ridge at BIOMEDevice Silicon Valley this fall

Want to learn more about 3D printing and regenerative medicine? Axiom Space will present current biomedical products being researched and developed at the BIOMEDevice Silicon Valley conference this November. We’ll be there too!

Sources

- ISS National Lab. Last accessed 8/18/2023.

- Redwire Space. Last accessed 8/18/2023.

- Keynotes | BIOMEDevice Silicon Valley. Last accessed 8/18/2023.

- Ax-2 Mission Research — Axiom Space. Last accessed 8/18/2023.

- Ax-2 Astronauts Splash Down, Completing Second Private Mission to ISS — Axiom Space Redwire’s 3D Bioprinter Successfully Installed on Space Station and Prepped for Upcoming Meniscus Print | Redwire Space. Last accessed 8/18/2023.

- BFF-Cardiac (nasa.gov). Last accessed 8/18/2023.

- Space Station Research Explore on NASA.gov Last accessed 8/18/2023.