Introduction

Stress singularities are an unavoidable occurrence in any theory of elasticity

regardless if the calculations are done by hand or simulated using software.

An artificial stress concentration occurs in areas where a sharp corner is

created and is sometimes unavoidable no matter what simplifications you do to

the geometry. In this blog I am going to show you a method to determine the

reach of the stress singularity and a safe distance when you can begin to

trust your results.

(click here for more information about stress singularities and

convergence)

Procedure

In order to determine the validity of the results I am going to do a

convergence test on nodes in the area of the stress singularity and see how

far the singularity effects. Usually when you refine the mesh the location and

assigned number of a node changes so I set up a grid system using split faces

and put sensors on the vertices of the grid. This forces a node in the corner

of the grid and the sensor ensures that I am getting the stress results at the

same location every time regardless of the mesh density and shape. The split

faces in the grid are a double blessing because I can use a

mesh control on the grid entities to refine the mesh only in the area

I am recording data. Once I have my results from multiple studies with

different mesh densities I will compare the stress results from each sensor,

look for convergence and determine the validity of the data at that location.

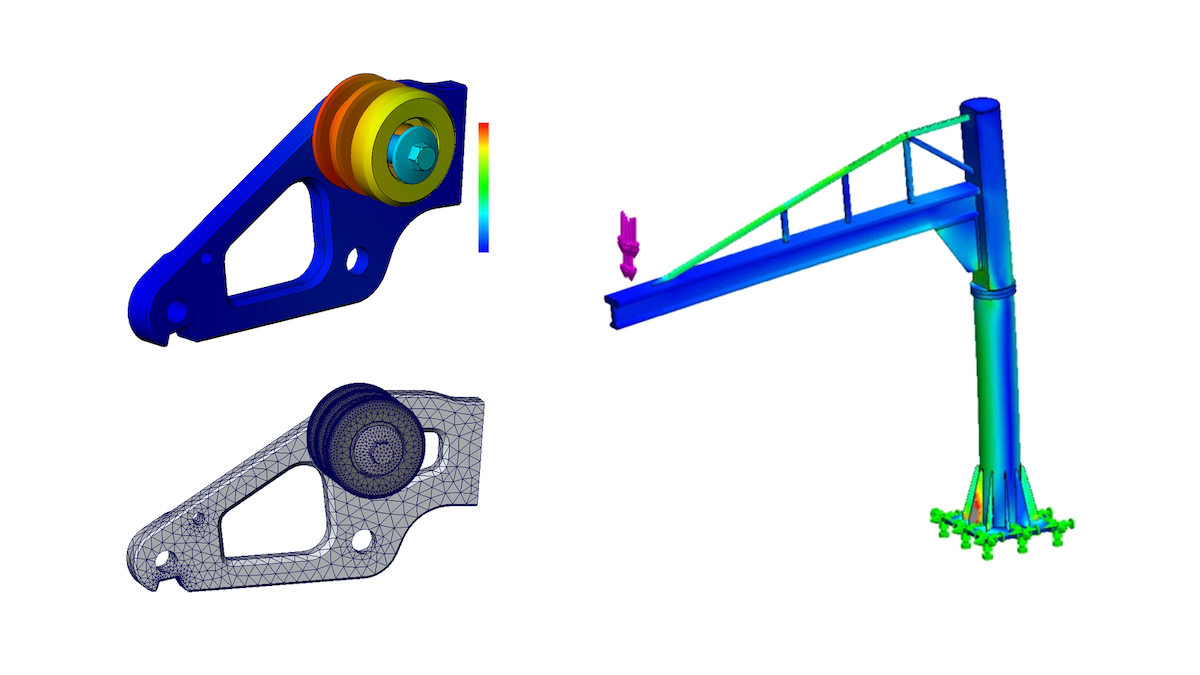

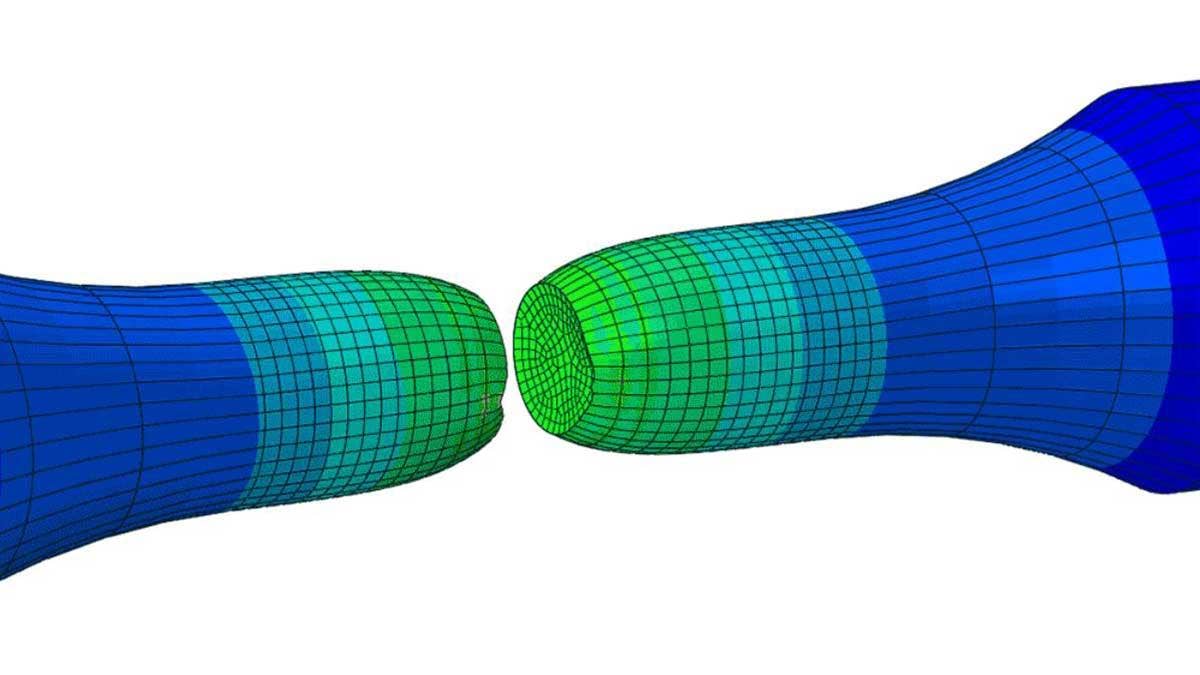

Example 1: Two Parts Contacting

Location of Singularity

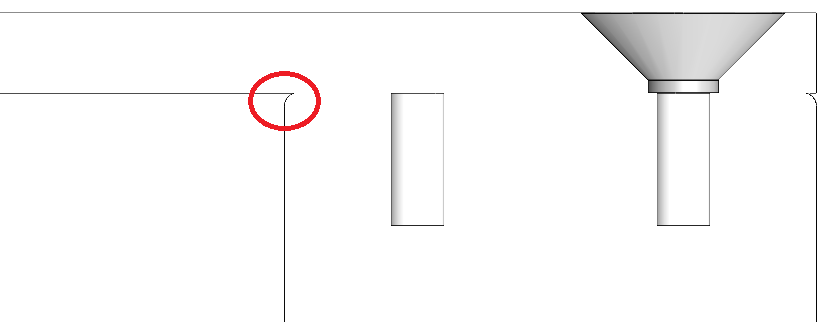

For this example I am not going to waste time explaining the boundary

conditions and contacts and only focus on the stress concentration itself

because I want to have one for this example. As you can see in Figure 1 and

Figure 2 a sharp corner is created right where the upper part leaves the

bottom part even though the bottom part has a fillet.

|

|

|

|

Set up of Grid and Sensors

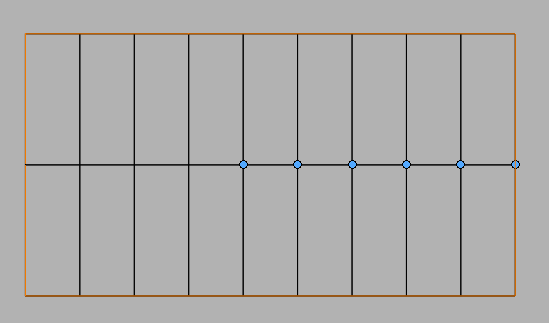

To create the grid I started with a sketch on the face that held the

stress concentration. I sketched a rectangle around the stress concentration

then used the segment tool to split the lines into equal segments

then inserted lines to create the grid. The linear pattern tool could

also be used for the same affect. Once I had the sketch I used the

split line tool to project the sketch onto the face resulting in

multiple faces, lines, and vertices that I am able to select for my

sensors and mesh controls. I placed 6 sensors on inner

vertices so I can get consistent readings in those locations. I named each

sensor the relative distance they were from the edge of the grid with the

names “Outside”, “0.02 in”, “0.04 in” etc.

|

|

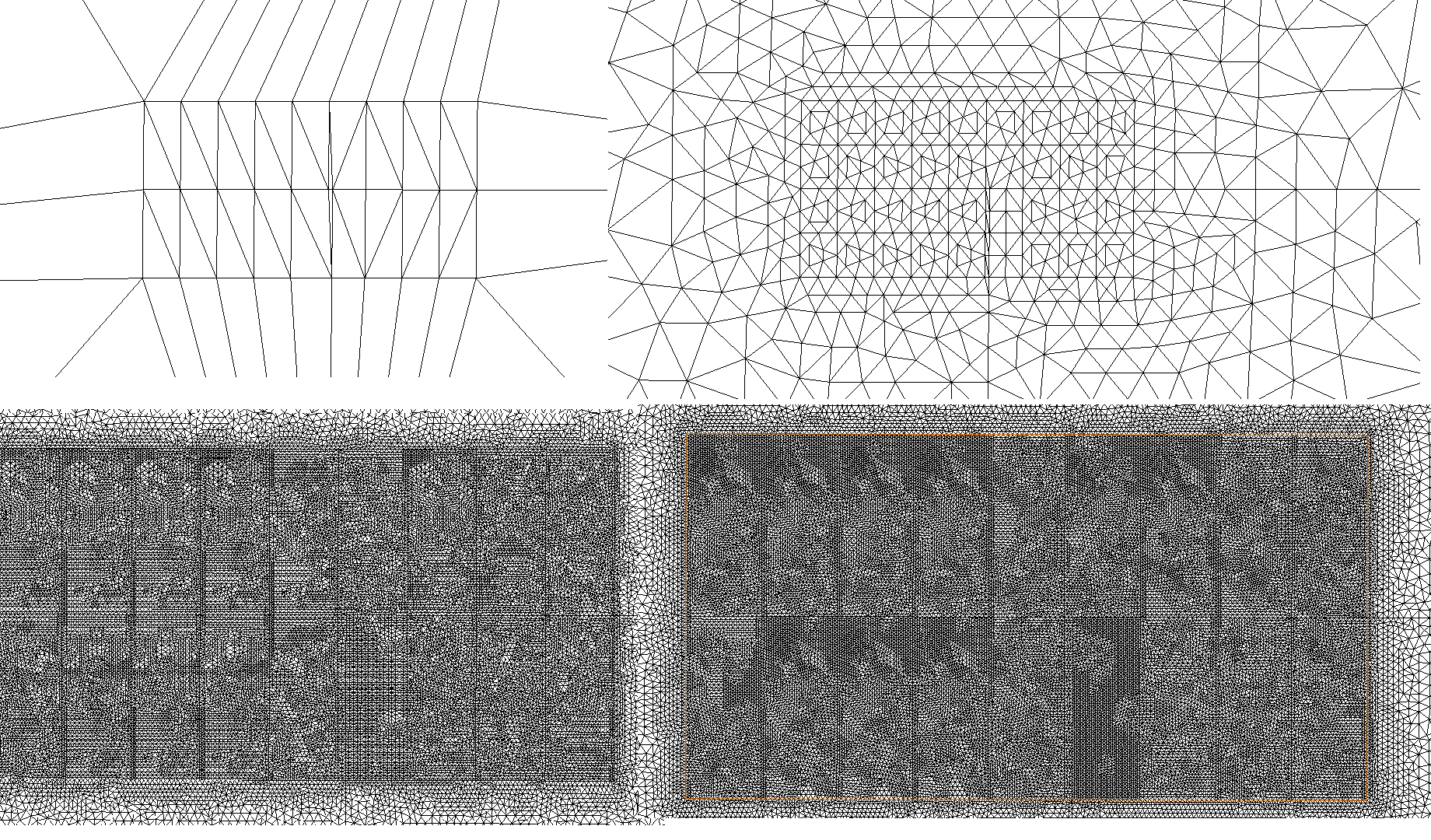

Mesh Refinements

For the convergence test I used 4 different meshes with a varying mesh control

applied to the faces on the sensor grid. As the mesh is refined more elements

are added to the grid increasing the amount of elements, nodes and the total

degrees of freedom in the system. Figure 4 shows graphically the intensity of

the mesh in the 4 runs and Table 1 lists the degrees of freedom in each study.

The mesh control was increased by an order of magnitude between the final 3

runs (0.1, 0.01, 0.001) in

Table 1: Degrees of Freedom in the Entire System for Each Mesh

Refinement

Run 1 |

Run 2 |

Run 3 |

Run 4 |

|

| DOF | 277062 | 399885 | 1483434 | 1628157 |

|

|

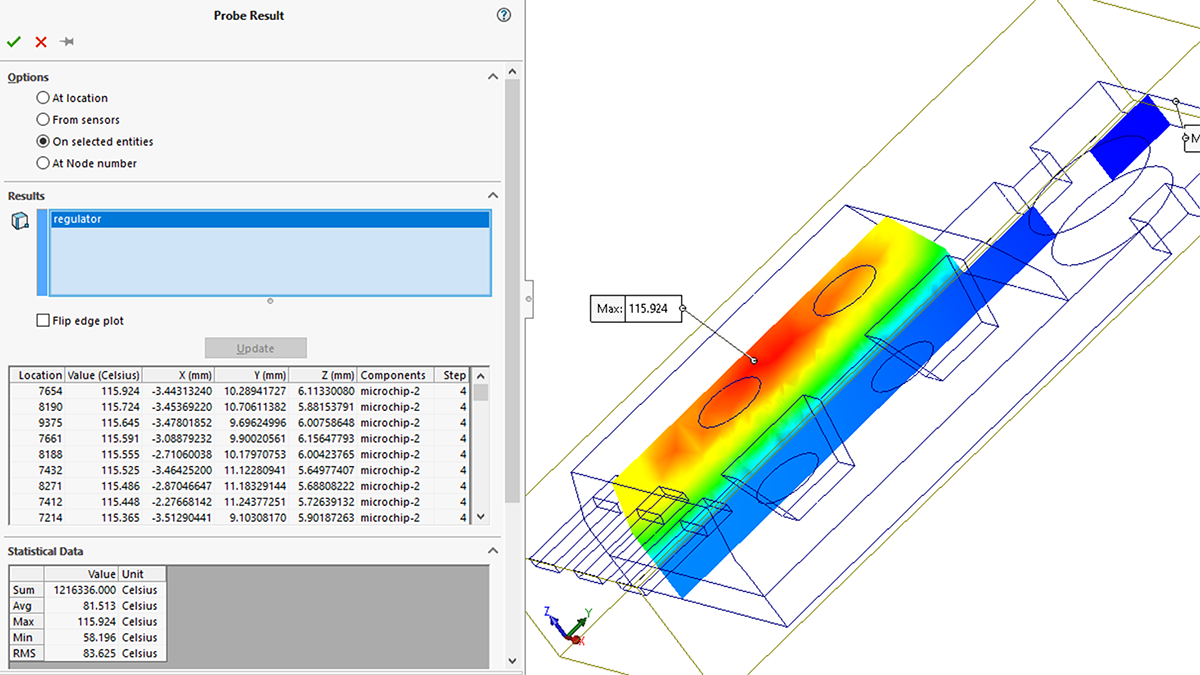

Results

First Run

The first mesh was rather coarse in regards to the sensor grid with only 2

elements per grid square. The stress values at the sensor locations are shown

in Table 2. This is a big discrepancy in such a small area so some mesh

refinement was definitely needed.

Sensor |

Von Mises Stress (MPa) |

| Outside | 6.66929 |

| 0.02 in | 7.30394 |

| 0.04 in | 7.34552 |

| 0.06 in | 11.0647 |

| 0.08 in | 17.3569 |

| 0.1 in | 65.4597 |

| Max | 116.959 |

Table 2: Von Mises Stress at Sensor Location for the First Run

Second Run

The second mesh has 14 elements per grid square and tells a different story.

All of the stress values are higher as shown in Table 3.

Sensor |

Von Mises Stress (MPa) |

| Outside | 15.0691 |

| 0.02 in | 15.9168 |

| 0.04 in | 17.2586 |

| 0.06 in | 19.6129 |

| 0.08 in | 23.6242 |

| 0.1 in | 111.182 |

| Max | 233.795 |

Table 3: Von Mises Stress at Sensor Location for the Second Run

Third Run

The third mesh has a significant refinement and I don’t even want to try and

count the number of elements in each grid. The degrees of freedom increased by

270 percent but most of the stresses only increased by under 10 percent. This

is a sign that the values are converging. The recorded values at each sensor

location for the third run are shown in Table 4.

Sensor |

Von Mises Stress (MPa) |

| Outside | 15.0539 |

| 0.02 in | 15.738 |

| 0.04 in | 16.7172 |

| 0.06 in | 18.4528 |

| 0.08 in | 22.5707 |

| 0.1 in | 80.1137 |

| Max | 622.995 |

Table 4: Von Mises Stress at Sensor Location for the Third Run

Fourth Run

The fourth and final run only saw an increase in the degrees of freedom by 10

percent but the stress at the singularity location changed by more than that.

Most of the sensors on the other hand changed by less than 1 percent and

taking into consideration the significant digits of the input load there was

no change at all.

Sensor |

Von Mises Stress (MPa) |

| Outside | 15.0219 |

| 0.02 in | 15.7525 |

| 0.04 in | 16.8399 |

| 0.06 in | 18.6981 |

| 0.08 in | 23.0476 |

| 0.1 in | 75.7974 |

| Max | 532.041 |

Table 5: Von Mises Stress at Sensor Location for the Fourth Run

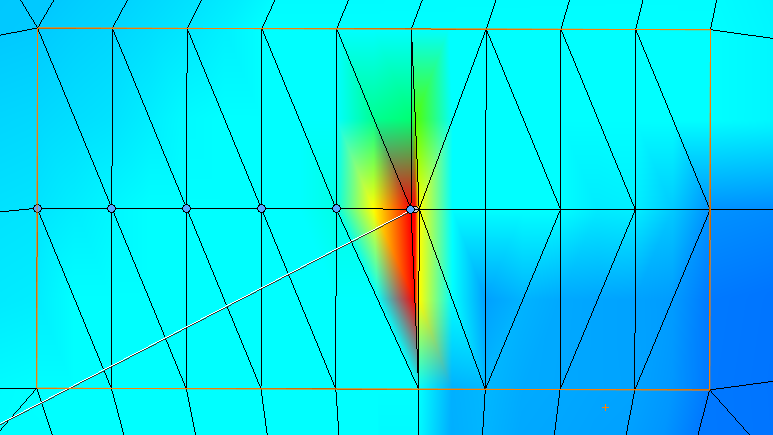

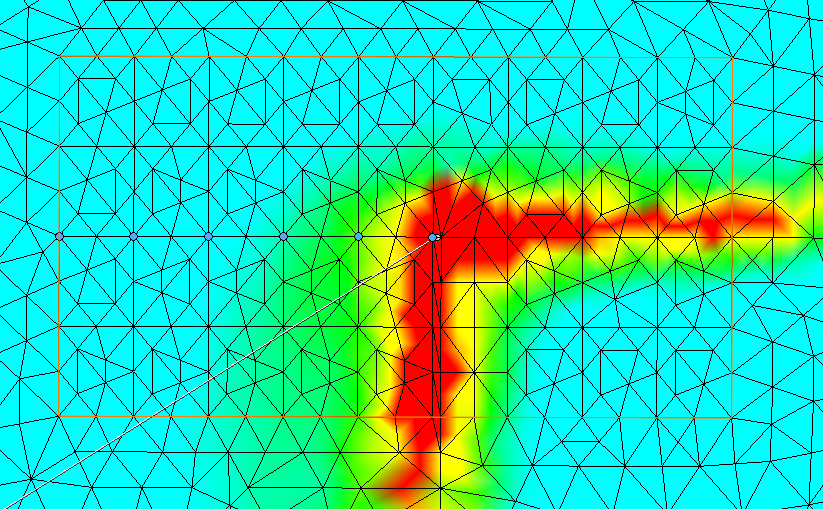

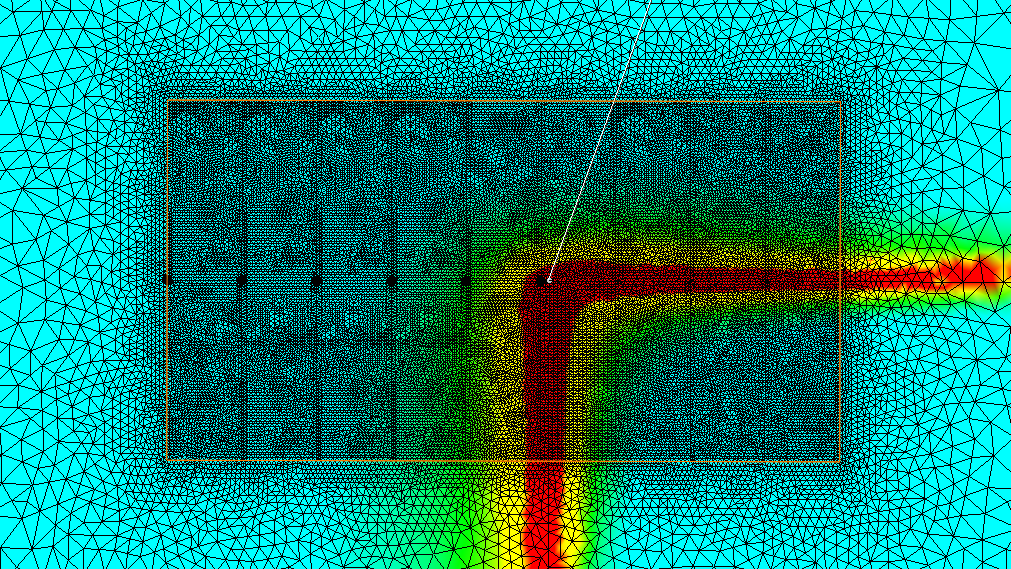

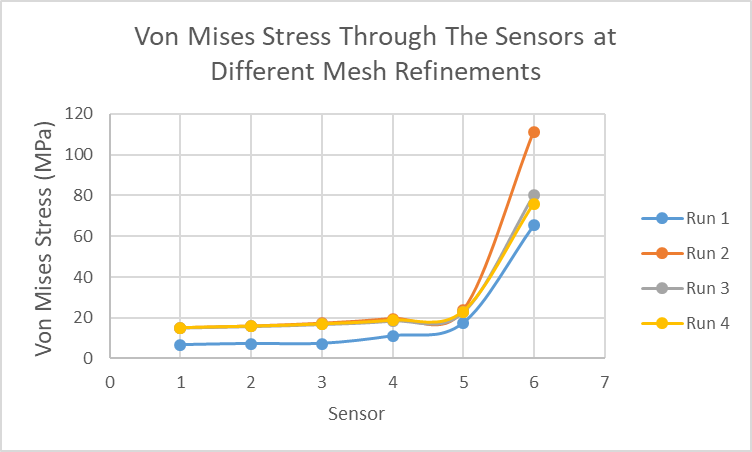

Graphical Results

|

|

|

|

|

|

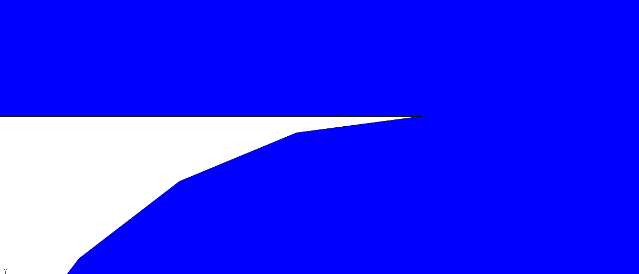

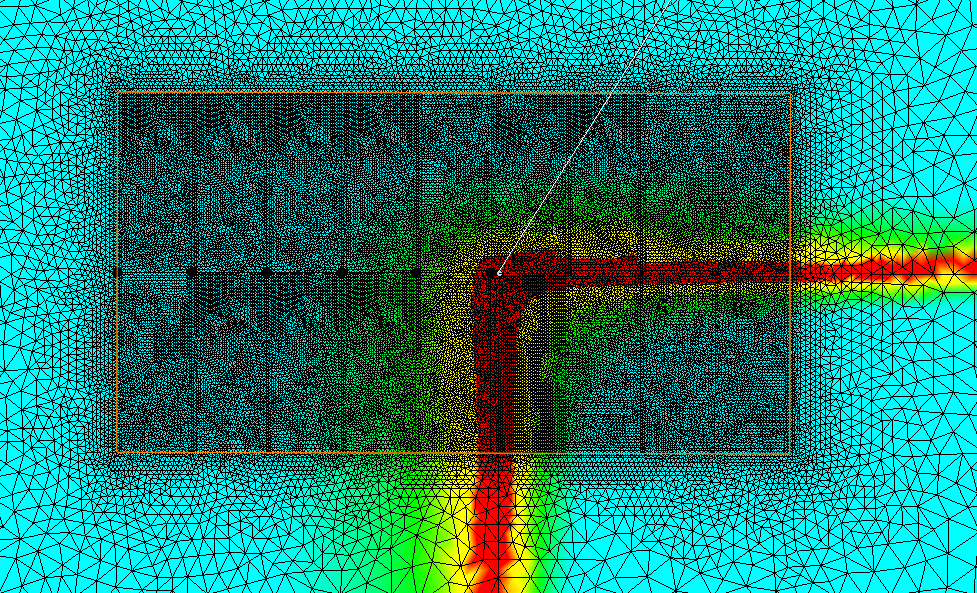

Figure 5 through Figure 8 is a graphical representation of the Von Mises

stress in the grid. The Grid is outlined in orange and the sensors are

emphasized by a blue or black dot. The red colour of the plot has been set to

the material yield strength. As the mesh is refined we can see the stress push

outward and then become more defined and have discrete boundaries. We can also

see that most of our sensors are below yield so the values are within the

assumptions of a static study.

Convergence Plots

|

|

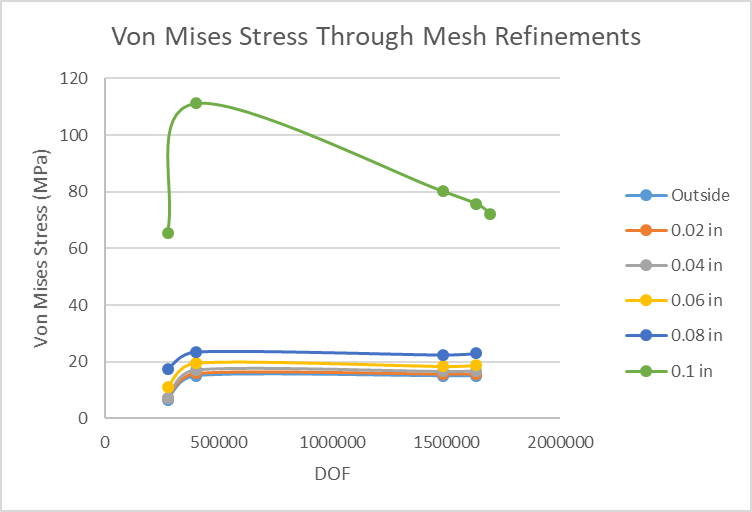

As we can see in in Figure 9 all the stresses increased after the first

refinement and the majority of them converged after continued mesh refinement.

The sensor located 0.1 in from the outside tells a different story. The value

tends to have a rather linear decrease with each mesh refinement and adding

another data point to that is further evidence that the sensor is not

converging. With more mesh refinement we might be able to get the value to

converge but I am very close to maxing out my hardware while creating my mesh.

|

|

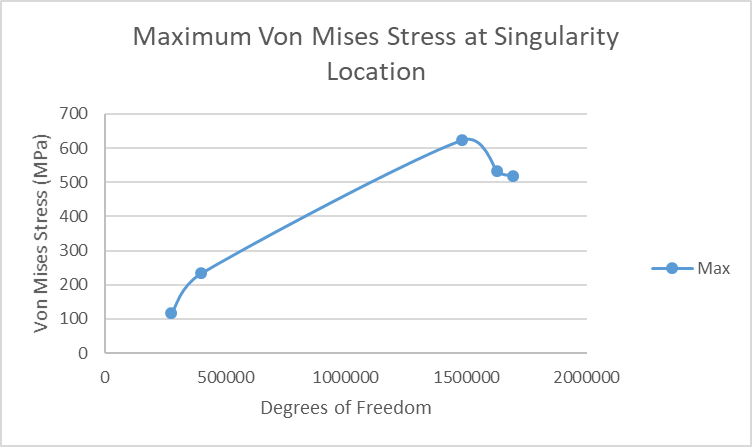

I left the singularity in its own plot because the high stress values would

have distorted the plot of the other sensors. As we can see in Figure 10 we

get a very large increase in stress with the increase in the degrees of

freedom and reduction of element size. This points towards a mathematical

singularity.

|

|

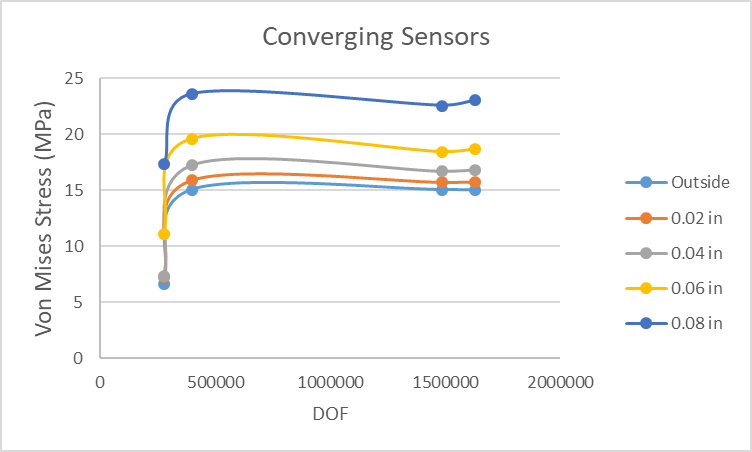

Figure 11 is a plot with a better resolution for the sensors that experience

convergence. With this plot we can also see the trend of how the stress

decreases as it moves away from the singularity. Again remember that I named

my sensors by their distance from the outside of the grid, meaning the bigger

the number the closer to the singularity they are.

|

|

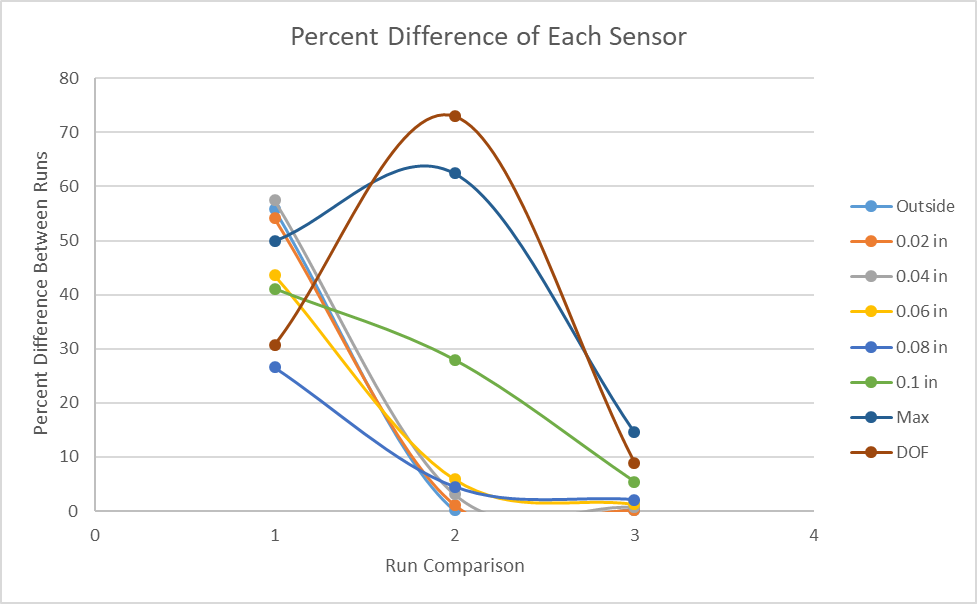

Figure 12 is another way of visualizing convergence. The x axis represents the

sensors and the y axis is the stress experienced for each run. We can see that

the stresses for runs 2, 3, and 4 are almost identical for the first 5 sensors

which converge but split apart at the sixth sensor. The sixth sensor or sensor

0.1 in seems like it is converging around the 80 MPa mark but further data

would be needed to confirm that.

|

|

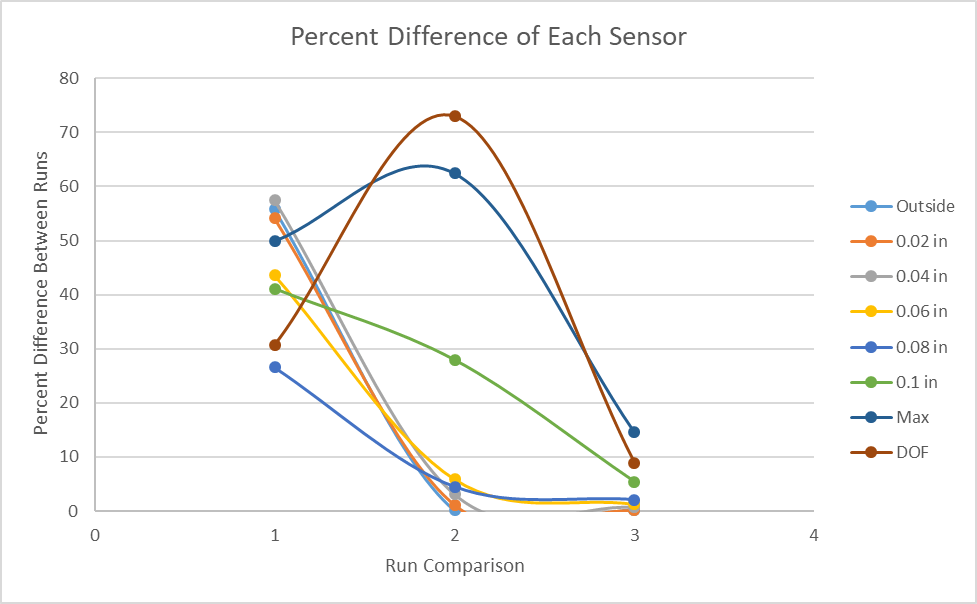

Figure 13 is the percent difference calculated between each run for the

sensors and degrees of freedom. Point 1 on the x axis is the difference

between runs 1 and 2, point 2 is the difference between runs 2 and 3, and

point 3 is the difference between runs 3 and 4. At point 2 we can see a

massive change in the degrees of freedom but a very small change in the

converging sensors. The data used to create the plot is shown in Table 6 to

better understand the plot.

Table 6: Percent Difference of Von Mises Stress and Degrees of Freedom for

Successive Runs

Percent Difference |

|||

| Sensor | Run 1-2 | Run 2-3 | Run 3-4 |

| Outside | 125.95 | 0.10 | 0.21 |

| 0.02 in | 117.92 | 1.12 | 0.09 |

| 0.04 in | 134.95 | 3.14 | 0.73 |

| 0.06 in | 77.26 | 5.91 | 1.33 |

| 0.08 in | 36.11 | 4.46 | 2.11 |

| 0.1 in | 69.85 | 27.94 | 5.39 |

| Max | 99.89 | 166.47 | 14.60 |

| DOF | 44.33 | 270.97 | 9.76 |

Conclusion

So I can conclude that the first 5 sensors are converging and the stress

results displayed are independent of the mesh. As an aside there is a

negligible difference between the nodal and elemental solution in the region

of the sensors giving me further confidence in the results. Sensor 0.1 seems

to be tending to converge but since it is over the material yield strength the

exact value is obsolete as we are in a linear study.

Table 7: Distance Sensor is From Singularity and if Convergence is

Reached

Sensor |

Distance From Max Stress (in) |

Distance From Max Stress (mm) |

Converged |

| 0.1 | 0.0011 | 0.028 | no |

| 0.08 | 0.0214 | 0.543 | yes |

| 0.06 | 0.0417 | 1.059 | yes |

| 0.04 | 0.0620 | 1.574 | yes |

| 0.02 | 0.0822 | 2.089 | yes |

| Outside | 0.1025 | 2.604 | yes |

So as we can see we were getting converged results half a millimeter or two

thousandths of an inch from the singularity location. Now that is really

close but I am going to do another test on a different singularity and try to

replicate my results. This blog is continued in Part 2.

For more information, check out our YouTube channel, get a

SOLIDWORKS Simulation quote or contact us at Hawk Ridge Systems today. Thanks for reading!