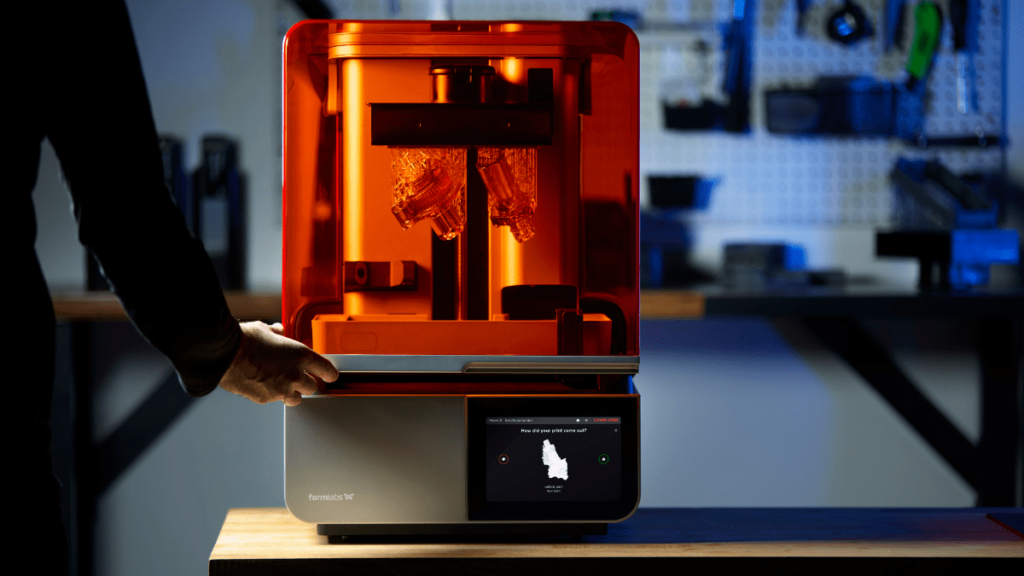

Formlabs, a leading innovator in 3D printing technology, has introduced the Form 4, a revolution in professional resin 3D printing. The Form 4 breaks through speed barriers, surpasses accuracy expectations, and boasts unmatched reliability, making it the ideal tool for designers, engineers, and manufacturers across a wide range of industries and applications. In this article, we’ll go into the top reasons why you’ll want to add the Form 4 to your arsenal of manufacturing tools.

At a glance, why you should check out the Form 4:

- Extremely fast print speed

- Anyone can learn to use it in less than 15 minutes

- Precision that rivals injection molding

- Automated post-processing

- Open Platform

- Remote monitoring

Breakthrough Speed for Agile Workflows: Most Prints Done in Under Two Hours

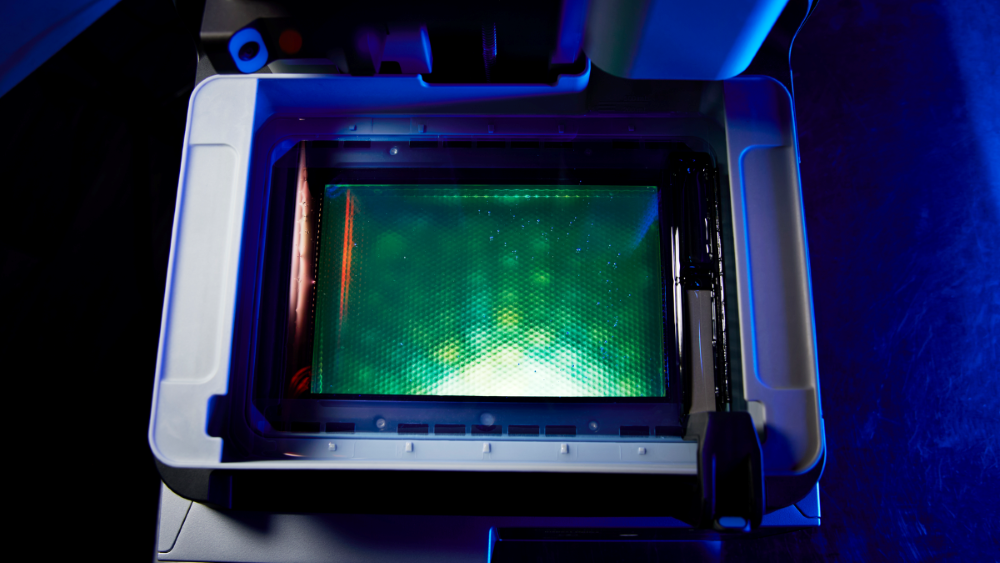

With its groundbreaking Low Force Display™ print engine, the Formlabs Form 4 shatters limitations in resin 3D printing speed. This innovative technology utilizes a powerful combination of high-powered LEDs and collimating lenses to rapidly cure thin layers of resin with exceptional precision. Unlike traditional SLA printers where print speed is limited by layer complexity and build volume, the Form 4 cures each layer instantly, regardless of part complexity or quantity.

This translates to print times up to four times faster than previous Formlabs printers, even for tall parts or batch printing. Now you can complete intricate prototypes or small production runs in under two hours, revolutionizing your design iteration cycles and production timelines.

Uncompromising Accuracy for Flawless Results

While speed is crucial, exceptional quality remains paramount. A precisely calibrated Light Processing Unit (LPU) with a best-in-class 50 µm XY resolution ensures outstanding dimensional accuracy and surface finish. Parts printed on the Form 4 consistently meet and exceed design specifications, guaranteeing tight tolerances for functional prototypes.

This translates to seamless assembly line integration, where parts click into place without additional adjustments. Even for end-use parts, the Form 4 delivers a level of detail and surface quality that rivals injection-molded plastic, eliminating the need for post-processing steps like sanding or smoothing.

Intuitive and Effortless Workflow for Seamless Operation

The Form 4 prioritizes user experience from the moment you unpack the machine. A simple and intuitive workflow streamlines setup, monitoring, and material changes, enabling you to print within 15 minutes. Automatic resin dispensing with smart sensors optimizes material usage and minimizes changeover time between prints. Gone are the days of messy resin handling and lengthy calibration processes.

Formlabs’ included PreForm software further simplifies the process with automated print preparation features. PreForm meticulously analyzes your 3D model, recommending the optimal orientation, support placement, and material settings for each project. This eliminates the guesswork and ensures flawless printing from the very first layer.

Built for Endurance and Reliability

The Form 4 is engineered to thrive in demanding production environments. Extensive quality control ensures each printer meets rigorous performance standards before leaving the factory. Key components, including the Resin Tank and Build Platform, have been re-designed for extended lifespans, even under high-volume printing conditions.

The improved sensor system proactively detects potential issues, allowing for adjustments to maintain smooth operation. With a reliable and consistent printing experience, the Form 4 minimizes downtime and keeps your production running smoothly, day in and day out.

Unparalleled Material Versatility and an Open Platform to Broaden Your Horizons

The true power of the Form 4 lies in its compatibility with Formlabs’ industry-leading library of over 23 unique resins. This expansive selection caters to a diverse range of applications. Whether you need biocompatible materials for medical devices or high-performance resins for engineering prototypes, the Form 4 has you covered. For applications requiring flexibility, such as creating functional models with moving parts, there are even specialized elastomeric resins available.

The launch of the Form 4 coincides with the introduction of six new resin formulations. These next-generation materials offer enhanced properties like improved clarity, a smooth matte finish, and sharper part details.

The Open Platform option on the Form 4 allows for exploration with certified third-party resins and customized settings, further expanding your material options and unlocking a world of creative possibilities.

The Future of Resin 3D Printing is Here

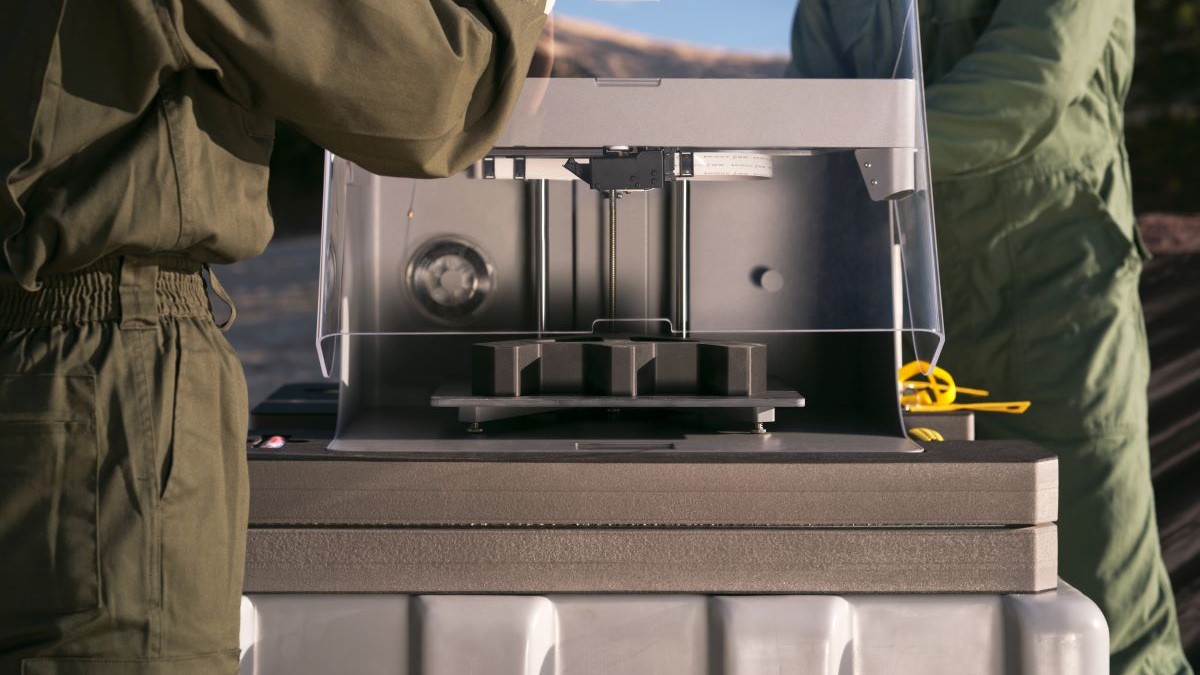

The Form 4 represents a significant leap forward in resin 3D printing technology. Its exceptional speed, unmatched accuracy, user-friendly design, and vast material selection make it an invaluable tool for designers, engineers, and manufacturers in various fields. From rapid prototyping and low-volume production to creating functional end-use parts, the Form 4 empowers you to bring your ideas to life faster and with unmatched precision. With the Form 4, the future of 3D printing is here, and it’s ready to transform your workflow.

Get in touch with Hawk Ridge Systems if you’re ready to learn more about the new Form 4.