3D printing has come a long way in the last 10 years.

With the incredible advancement in print technologies, there has been a major increase in industry adoption and use. 3D print users in almost every industry are reaping the benefits of faster lead times, reduced part costs, and improved operational efficiency:

- L’Oréal reduced costs by 33% by using HP 3D printers to prototype and label products more efficiently.

- ASC (Aaron Sims Creative) used Formlabs 3D printers to bring the demogorgon from Netflix’s “Stranger Things” series to life.

- The U.S. Army uses Markforged printers to print low-volume production parts, saving $200k on one replacement part alone.

But these customers didn’t just adopt 3D printing overnight. We’ll break down the three steps to consider when you are looking to bring in 3D printing technology to your business.

- Identify Key Applications for 3D Printing

- Figure out what type of 3D Printer You Need

- Quantify Your 3D Printing Workflow with Tangible ROI Metrics

Step 1: Identify Key Applications for 3D Printing

3D Printing is just for end-use parts. Many organizations use it for tooling, jigs, fixtures, and prototypes too. To figure out where 3D printing can help the most, it helps to identify which parts of your workflow slow you down the most.

It could be something as simple as producing in-house jigs and fixtures instead of waiting for a part to come in. When undertaking a 3D printing strategy, the primary driver of success will be finding these types of applications within your organization.

We often see individuals in companies reach out to various internal departments looking for bottleneck applications, part shortages, and general inefficiencies that could benefit from 3D printing.

Some questions to consider when you’re trying to uncover these use cases:

- What is the current cost and resource investment to obtain a part using current means?

- What is the time delay or workflow downtime?

- What are the part requirements from a mechanical perspective?

- What are the current loading conditions, temperature exposure, and part lifecycle?

- How many parts do you need today versus what you need to scale?

Once you have some answers to these questions, you’ll have what you need to consider what type of 3D printer you need.

Step 2: Figure Out What Type of 3D Printer You Need

There are several different 3D printing technologies out on the market, but which technology is the right fit for your needs?

Here at Hawk Ridge Systems, we specialize in a wide range of print technologies across our portfolio of Markforged, Formlabs, and HP printing systems.

Each company and printer lineup boasts specific advantages and offerings that can fill the need from prototyping all the way through to full-blown production.

There are three broad categories of additive manufacturing equipment which can be divided by the raw material feeding each style of print system.

The three categories are:

- Filament-based systems like Markforged

- Resin-based systems like Formlabs

- Powder-based systems like HP and Formlabs

Markforged 3D Printers: Heavy-Duty Printing, including Metal

Markforged specializes in fused filament fabrication (FFF) and continuous fiber reinforcement (CFR).

These 3D printing systems produce incredibly strong composite parts to the point that they can potentially replace aluminum components on the factory floor.

Markforged also has software called Eiger backing their printing systems with advanced features such as simulation to dial in part designs before printing. Markforged 3D printers are workhorses perfect for the most demanding applications.

Markforged also has a strong offering in the metal 3D printing world with the Metal X system which utilizes FFF print technology which is similar to the composite systems. The ease of use and variety of materials such as 17-4 Stainless Steel, Copper, Inconel, and several tool steels make the Metal X the best place to start when looking for a metal 3D printing system.

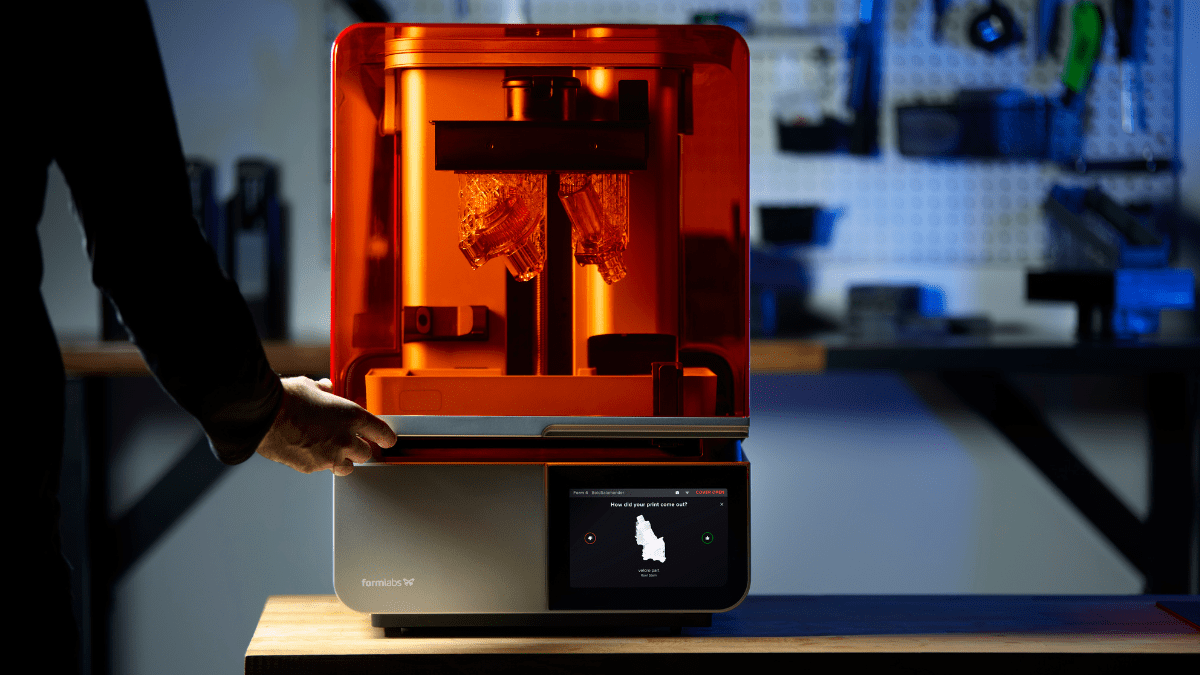

Formlabs 3D Printers: Easy to Learn and Creates Super-Fast Prints

Formlabs specializes in stereolithography (SLA), and selective laser sintering (SLS) printing systems and they are an industry leader in both categories.

SLA is a resin print process that allows for printing very fine details. You can use a wide variety of material options including transparent, bio-friendly, elastomers, durable resins, and much more.

Formlabs SLA 3D printers are extremely versatile and can meet a huge range of mechanical property requirements from very soft to extremely hard properties as well as extreme heat and chemical resistances.

Formlabs SLS technology made a big splash in the market as soon as it was released in 2021, and they’ve continued to innovate with their latest Form 4 printer. The Form 4 has an Open Platform license so you can use third-party materials and can make most prints in as little as under two hours.

With the Formlabs Fuse 1 platform, SLS printing has become much more affordable and user-friendly. Formlabs SLS is a powder bed print technology that allows for faster production times and much more design freedom. Users can make injection mold-like parts that are ready for end-use applications.

The Formlabs ecosystem allows for a high degree of scalability and automation with both the SLA and SLS print platforms. Read more about the differences between SLA and SLS printing.

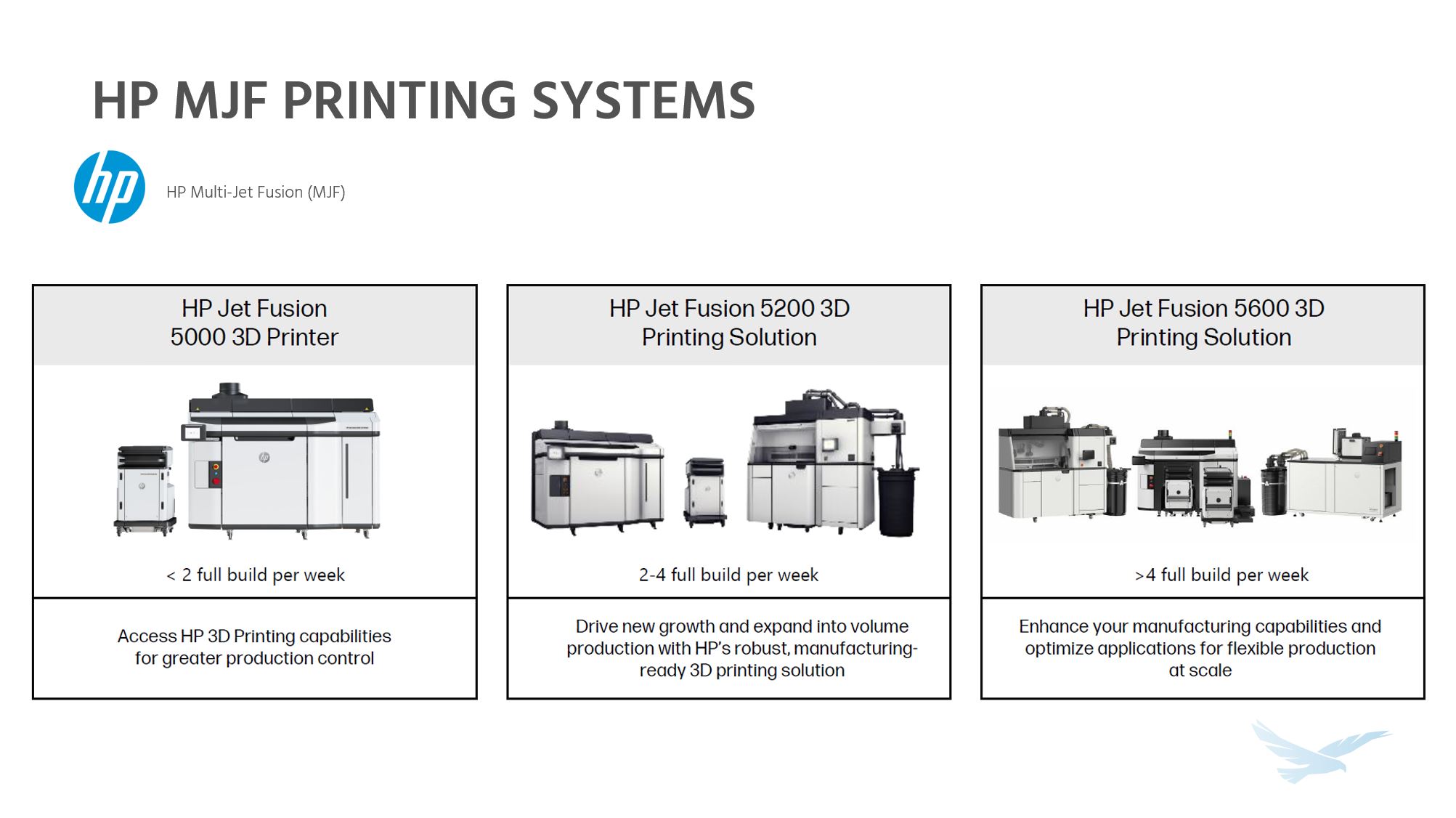

HP 3D Printers: Great for Industrial Use-cases and Ideal for Large Prints

HP is a big player in the production print market with its Multi-Jet Fusion (MJF) powder bed print platforms. The MJF printing systems such as the 5600 have a larger build volume at 15” x 11.2” x 15”. This build chamber size coupled with incredible print speeds makes this system a top performer in powder bed printing.

Providing excellent part quality coupled with world-class user experience, HP has dialed in production printing and brought it to the mainstream. When you see the top part service providers in the world consistently pumping out MJF parts, it becomes clear that MJF is a dominant industry force for high-volume part production.

HP also recently lowered the barrier to entry with the release of the 5000 series machine which is geared towards those who are just getting started. The MJF platform allows for scaling into the production models with the 5000 series machine as a base.

So, Which 3D Printer Should I Choose?

There is not a single technology that is the best in all circumstances. What we have found is that each printing system has unique advantages and use cases.

While there is certainly crossover in the applications that each system can achieve, there are several key differentiators that can help narrow down which system will be a good fit:

- Material mechanical properties

- Production volumes

- Part cost

- Part size

- Workflow

- Total cost of ownership/equipment cost

- Facility space considerations

All these factors will play a big role in determining which system is right for you, and you might even find that a combination of 3D printers will best suit your various needs.

Step 3: Quantify Your 3D Printing Workflow with Tangible ROI Metrics

There are four primary ways that 3D printed parts can add value and replace traditional manufacturing for specific use cases.

1. Reduced Part Cost

The most straightforward way to understand if 3D printing is going to provide value is to run a cost analysis comparing an additive manufacturing solution with the current method of part acquisition.

Print software like Markforged Eiger will immediately provide part cost and print times as soon as a file has been sliced making it incredibly easy to calculate part cost savings. The best part is that Eiger software is free to use. We often see that 3D printing results in major savings when compared to outsourced custom manufacturing, in-house manufacturing, or buying parts off the shelf.

2. Reduced Lead Time

Long lead times can be crippling to manufacturing operations. 64% of manufacturers report supply chain disruptions as one of their top challenges to address.

We see many companies switching to additive manufacturing for this reason. Whether parts are sourced from an overseas distributor, local manufacturer, or in-house machine shop, bottlenecks and delays can be very common.

3D printing in-house removes the variability of an outside source and allows for more control of the process and timings. With improved lead times due to 3D printing, it allows for much higher efficiency and profitability.

When considering adding 3D printing to your business, it’s important to get metrics to support your investment. Those metrics could be in the form of time saved, downtime avoided, lower cost per part, or other creative ideas.

For example, Guhring UK used Markforged 3D printers to reduce lead time by up to 66% for production parts and reduced their low-volume tooling costs by 75%.

3. Reduced Human Labor

Human labor in producing a product through traditional means will vary depending on the process. With additive manufacturing, lights-out production is the norm.

Having a machine work unattended throughout the day, overnight, and on weekends is a valuable ability that 3D printing brings to the table.

This time saved allows employees to focus on other high-value tasks while the printer is running jobs for you. In an ROI analysis, you can also quantify how many man-hours you’ll save.

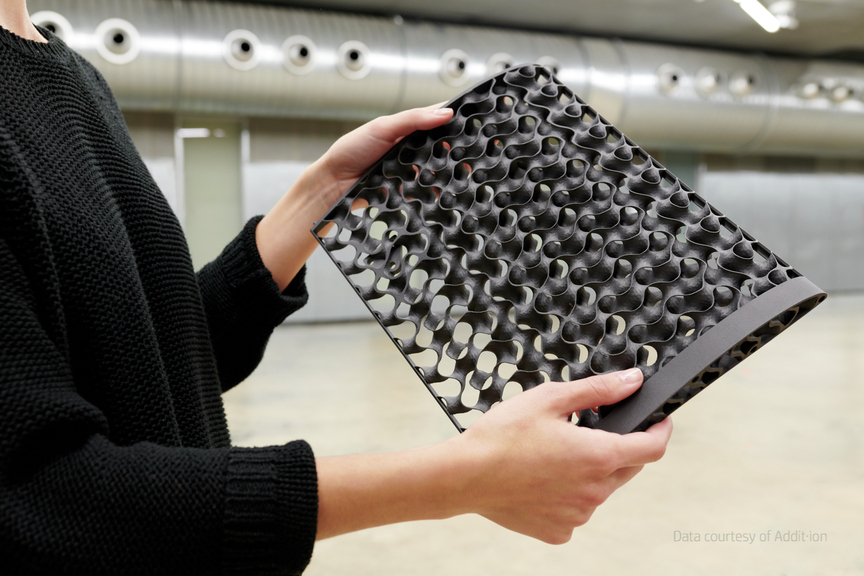

4. Complex Design Requirements

Complexity often leads to sharp price increases with traditional manufacturing methods. Additive manufacturing does not have this same limitation. Complexity can be achieved at little to no extra cost.

Not that we’re recommending making things more complex just because you can, but because complex geometries have unique benefits, specifically for aerospace and automotive applications.

With 3D printing, complex geometries are possible that you can’t get with traditional manufacturing.

For a quick guide to calculating your savings check out our post on how to measure return on investment for bringing in 3D printing.

By following these tips and tricks, you are sure to reap major benefits with your 3D printing strategy. For pricing and more info about industrial 3D print systems, contact us at Hawk Ridge Systems.