The rising demand for customization challenges manufacturing fundamentals like standardization. But things change, and what has worked in the past may not be best practice today.

In light of this shift, companies must rethink their approach. Mass production and uniformity no longer apply. Instead, you need sustainable, flexible and customizable design and manufacturing workflows that cater to built-to-order requirements.

In this blog, we’ll explore the trends and challenges shaping how modern manufacturers and designers handle custom built-to-order machine designs. We’ll shed light on two solutions you can implement to meet customer demands while maintaining efficiency and cost-effectiveness.

Key Trend: Higher Demand for Customized Solutions

Today’s industrial equipment customers demand personalized solutions. They seek products that align perfectly with their operational requirements.

Teams are tasked with understanding and fulfilling highly specific needs. Various departments—from sales to engineering and manufacturing—must work together more seamlessly than ever before. This can be time-consuming and resource-intensive, particularly for those without the tools, processes, and a company culture that supports collaboration.

In addition, customers want custom parts delivered at prices as close to those of standard products as possible. And, personalization expectations extend beyond design and delivery; customers also anticipate excellent service. This involves fast responses to questions and inquiries, efficient problem-solving, and after-sales support.

5 Challenges Affecting Your Built-to-Order Process

To thrive in industrial equipment design and manufacturing, your company must adapt to changing customer expectations. This is crucial to remaining competitive and positioning yourself as a trusted industry player.

But in a fast-evolving industry, you face several significant challenges. These include:

1. Slow Time to Market

Let’s examine the build-to-order machine design and manufacturing process. Each custom order starts with a base model that requires various modifications or configurations. Typically, the customer requests additional changes after reviewing the initial design. Your team then iterates the design until the client gives their approval.

Even small changes add up over time, especially if you handle multiple orders concurrently. The process becomes lengthy and complex, involving many parties, from designers to engineers and customer service teams. As a result, the delivery of the final product is delayed. This can cause bottlenecks and lead to client frustration.

2. Tedious Design Iterations

Custom-designed machines generally go through several manual iterations before the client gives their final approval. Each change requires careful planning and execution, but this is only possible through clear and timely communication.

Designers must approach every modification with exceptional attention to detail, ensuring changes align directly with the client’s specifications. This undertaking is both time-consuming and prone to errors. Sometimes, multiple rounds of revisions are required before approval, slowing production and increasing the likelihood of mistakes.

3. Multiple Custom Order Management

Perhaps your design team can manage one or two custom orders. But what happens when you have several simultaneously?

Each order requires individual attention, which can push your resources to the limit. Balancing multiple projects can stretch teams thin, leading to delays, errors, and increased pressure

4. Repetitive Tasks

Designing custom machines often involves creating similar yet different designs. Making these small tweaks is repetitive work. It’s tedious and inefficient and can lead to burnout among your designers. Leveraging automation software can streamline these tasks and reduce redundancy.

5. Many Dependencies

Traditionally, custom machine design workflows are linear and dependent on sequential steps—task B cannot happen until task A is completed. This serial approach creates dependencies, which slow down the entire design and manufacturing process.

To combat this challenge, modern manufacturers should aim for parallel workflows that enable flexibility and design iteration alongside timely manufacturing.

2 Solutions to Overcome Customization Challenges

It’s unlikely design and manufacturing will revert back to the old days of standardization. Now’s the time to investigate and implement solutions that streamline and automate the design process for custom built-to-order machines. Consider the following strategies to meet changing customer demands—today and for years to come.

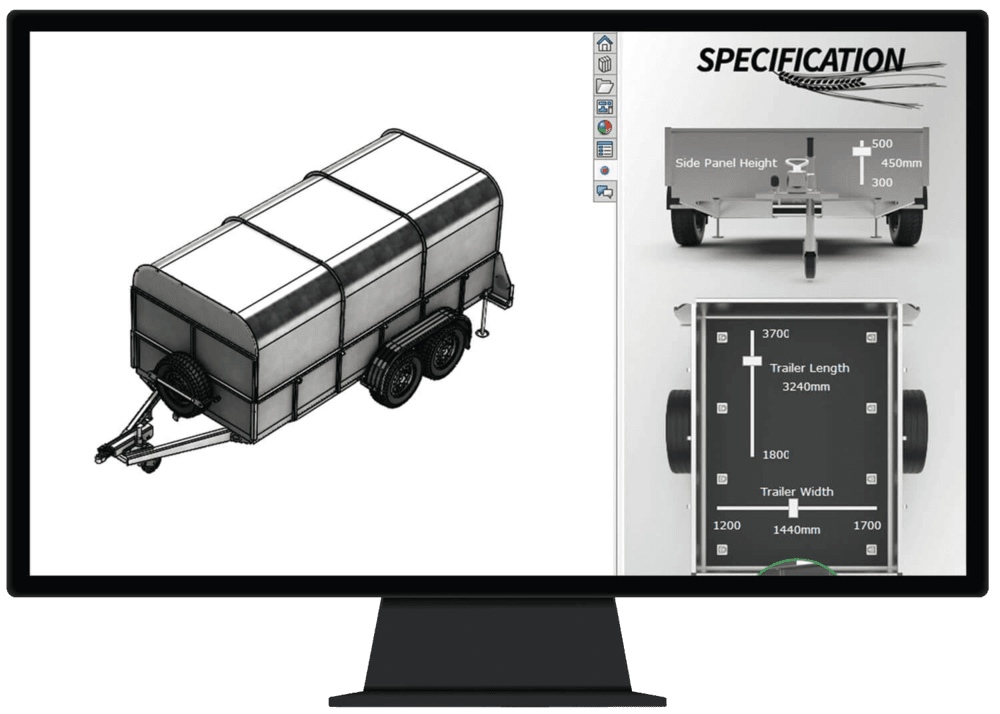

Solution 1: Use DriveWorks to Automate Custom Equipment Design and Manufacturing

The right software can significantly reduce the time and effort involved in designing custom machine parts.

A solution like DriveWorks automates repetitive design tasks, empowering engineers to focus on innovation and development. It cuts down on manual work and mitigates the risk of errors, allowing for a more efficient and future-proof workflow.

Some key features of DriveWorks include:

- Use predefined rules to create new design files. This feature ensures master files are not overwritten so you maintain the integrity of all original designs.

- Automatically generate manufacturing drawings that include all necessary views and annotations. This speeds up the production process, helping you get products to market faster.

- Automatically create custom branded documents like quotations and bills of materials. This improves accuracy and bolsters your professional image.

- Empower customers to configure products to meet their own needs and create accurate quotes and design drawings in minutes.

Completing repetitive tasks while maintaining pinpoint accuracy, automation frees up your engineers to innovate and excel. Here are some of the benefits:

Greater Efficiency

Automation optimizes resource allocation. It streamlines processes and reduces the resources and effort required for design activities, leading to faster project completion times.

Integrating DriveWorks with SOLIDWORKS—more on this below—provides real-time updates across multiple design aspects, further reducing the time spent on manual changes.

Fewer Errors

Consistency and accuracy are key tenets of good design. Using DriveWorks, you can automate tedious work that is prone to human error. Plus, design modifications are applied uniformly without manual intervention.

Cut Costs

When engineers no longer have to spend time on repetitive tasks, they have more bandwidth to dedicate to value-added activities such as designing new products and innovating existing ones.

Improved Customer Satisfaction

With tools and processes in place to meet the increasing demand for custom-built machines, your business can deliver precise products that delight your clients and win their loyalty. Proactive communication is guaranteed thanks to the automated creation of technical and visual documentation. All stakeholders can access up-to-date information, improving the overall experience.

Solution 2: Adopt a Parallel Workflow by Integrating Your Design Environment

Another effective way to handle custom built-to-order machine designs is to redefine your design-to-manufacturing workflow.

Serial workflows create dependencies that slow things down from initial designs to final production. But in a parallel workflow, multiple stages of the process happen simultaneously. For example, design teams can work on different parts of a machine at the same time while manufacturing staff prepare the necessary tools and materials for production. This approach reduces the waiting time between stages, accelerating the process.

Leverage an Integrated Design Environment with SOLIDWORKS

Parallel workflows are practical only if every team member is on the same page. Every person must have access to real-time information about a product and its design to prevent misunderstandings and mistakes.

SOLIDWORKS offers an integrated design ecosystem that connects design files across multiple tools in real time. Design revisions automatically update electrical schematics and technical documents, saving time on manual updates, reducing errors, and ensuring everyone involved in the design and manufacturing process, as well as the customer, is up-to-date. This improves coordination among different teams and empowers productive and impactful collaboration.

Tackle Customization Head-On

The demand for customization is here to stay. Equip your team with the automated tools they need to meet customer expectations and deliver exceptional, fit-for-purpose products.

Ready to try DriveWorks automation? Activate DriveWorksXpress in your SOLIDWORKS CAD license or start your 30-day free trial of DriveWorks Solo today.

To learn more about how SOLIDWORKS and DriveWorks can help you meet the demand for customized machines, contact us today.