In today’s fast-paced world, regardless of the industry, the race for innovation is relentless. The pressure to deliver cutting-edge products and solutions within ever-tightening deadlines is mounting, placing significant strain on engineers.

Engineers spend an astonishing amount of time, up to 33% of their working hours, on non-value-added tasks associated with managing design data.

In this blog, we will explore effective strategies and tools that empower engineers to streamline their workflows, reduce non-value-added tasks, and regain precious time for innovation.

We will cover the importance of leveraging advanced data management solutions, sharing insights and best practices to optimize productivity and accelerate time-to-market.

What Is Considered Non-Value-Added Work in Engineering?

While managing product design data is an essential aspect of the product development process, it can quickly become a time-consuming burden without the right tools in place.

As a result, innovation can suffer, and inefficient data management practices may hinder time-to-market goals.

Here are the six most common non-value-added tasks engineers encounter daily.

1. Searching for Data and Other Needed Information

Searching for data and other needed information consumes valuable time and slows down productivity. Engineers spend precious hours sifting through folders, file structures, and emails to locate the specific information they need, leading to delays in project execution and reduced efficiency.

2. Collecting Data from Others

Engineers often find themselves chasing after colleagues or stakeholders to gather required data, specifications, or feedback, resulting in prolonged lead times and disruptions to their workflow. This manual and time-consuming process can be frustrating, leading to decreased productivity and a drain on overall project effectiveness.

3. Checking Data In and Out

Engineers often manually check files in and out rather than spend time on actual design work. This process is prone to errors, such as files being locked or overwritten accidentally, further impeding progress and requiring additional effort to clean up the situation.

4. Incorporating Changes Made by Others

Incorporating changes made by others involves manually tracking and merging modifications across multiple design files or documents. Engineers may spend excessive time reviewing and incorporating changes made by colleagues or stakeholders, leading to confusion, potential errors, and a loss of productivity.

5. Recreating Lost Data

Engineers who can’t find critical design information spend time and effort reconstructing the lost data, including recreating models, redrawing drawings, or recompiling documentation. Recreating work delays project timelines and diverts valuable resources away from more valuable design activities.

6. Wasting Time on Conflicting Design Versions

With conflicting design versions, engineers can waste time working on the wrong version of a design file or encounter CAD data being overwritten. Engaging in work based on outdated or incorrect information leads to rework, confusion, and delays. Many engineers spend time rectifying mistakes, reconciling conflicting versions, and diverting attention and effort from more productive engineering tasks.

Is Non-Value-Added Work Hurting Your Team?

Non-value-added work can significantly impact your team’s productivity and business revenue. If these impacts aren’t noticeable now, they can be in the future.

Engineers spend about a third of their time on non-value-added work, such as recreating lost data and working with outdated CAD information. The time spent searching and reworking can easily translate to missed time-to-market and revenue. On a larger scale, non-value-added work can lead to the loss of the business.

Most non-value-added work is due to poor data management processes, which many engineers and companies recognize their product development processes need improving.

3 Solutions You Can Do Now to Reduce Non-Value-Added Work

Now that you know the six most common non-value-added activities that engineers face and their impact on your business, let’s add back time to your projects and tasks.

Here are the three solutions you can do now to reduce non-value-added work for your team.

1. Talk with Your Engineers About Their Time-Consuming Tasks

Your team may experience something similar to the most common time-consuming tasks related to product data. Schedule 30 minutes to an hour with each of your team members to understand their true pain points, where they are spending their time, and what non-value-added work they are doing from their perspective.

2. Improve Your Design Data Management Practices

Once you’ve talked with your team, consider reevaluating your design data management practices and processes. Look deeper into what is and isn’t working. Your evaluation can help you identify better processes and practices your team should adopt.

3. Determine If You Need Data Management Software

As you improve your design data management processes, you may need something more high-tech to help you instead of developing new processes and dedicating someone to enforce them. You can find several data management software available on the market. They can reduce design errors and time-consuming tasks with automation.

What Product Data Management Software Are Available?

Many engineers prefer one central platform for their product data management needs. A singular integrated platform allows everyone to collaborate and stay updated on changes and file versions.

Integrated data management systems enforce workflow processes, keep everyone on the same page, and automate repetitive, time-consuming tasks.

Often, companies are concerned with how a data management system can fit into their budget or how they can manage legacy data in the transition.

Here are two powerful, affordable product data management software that can successfully manage existing data migrations.

SOLIDWORKS PDM

SOLIDWORKS PDM simplifies workflows and improves collaboration within teams. The software enables users to efficiently manage and control design data, including documents, models, and drawings, throughout their lifecycle.

You can eliminate time-consuming manual processes, such as searching for files and manually updating revision numbers.

With robust permission controls and automated workflows, it helps you to enforce data integrity and consistency, reducing rework and design errors.

Multiple team members can work on the same project simultaneously, allowing for more collaboration and eliminating delays caused by file access issues.

With SOLIDWORKS PDM, you can focus on value-added tasks, improve efficiency, and accelerate time to market.

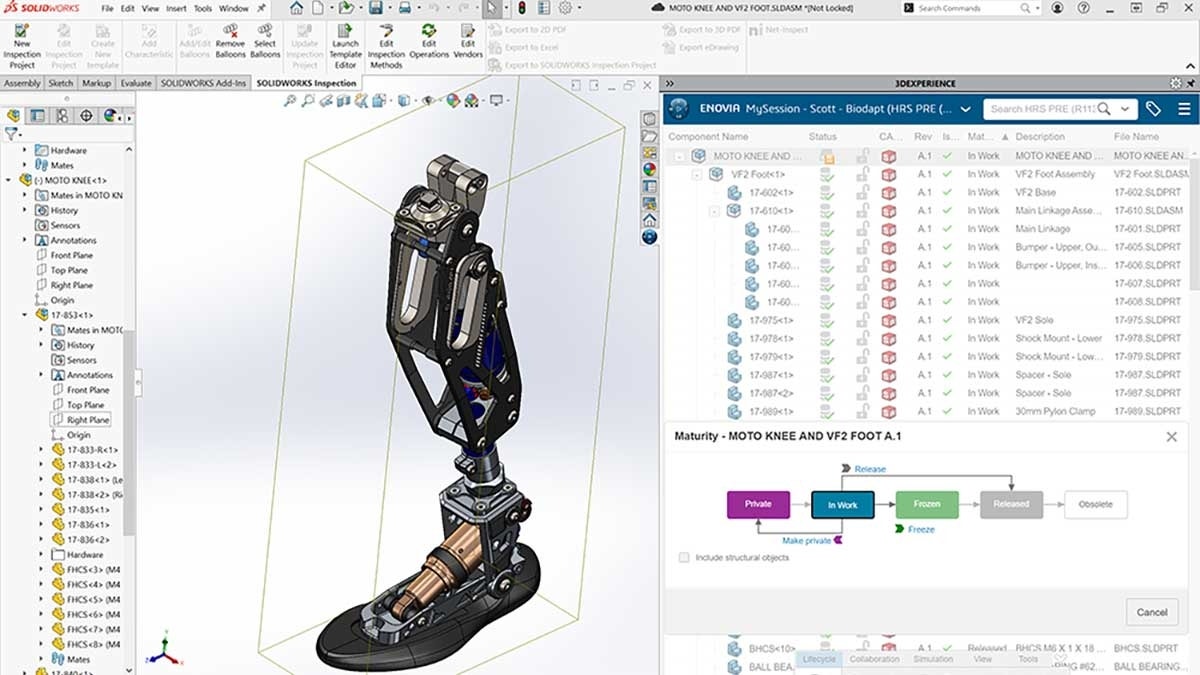

Collaborative Designer for SOLIDWORKS (3DEXPERIENCE Data Management Tools)

Collaborative Designer for SOLIDWORKS, a cloud-based platform as part of the 3DEXPERIENCE platform, enables real-time collaboration among team members, removing version control issues and the need for manual file transfers.

Collaborative Designer provides a centralized platform where all design iterations, comments, and changes are stored and automatically synced across users and devices. This eliminates the risk of working on outdated files and reduces time-consuming tasks, such as manually merging design changes.

Like SOLIDWORKS PDM, it simplifies managing design data and eliminates manual data synchronization. Multiple users can work on the same design simultaneously, making it easier to share ideas, make modifications, and quickly iterate on designs.

Engineers can focus more on value-added design work and innovation with Collaborative Designer.

The Bottom Line

Over time, non-value-added work can hurt your team’s productivity and company. You’ll want to reduce as many of these non-value-added activities as possible.

Consider your goals in the next year or two, especially if your business plans have tight time-to-market schedules and visions to double or triple in size.

Start talking with your team about their non-value-added work, creating more effective data management processes, and identifying process stages where PDM software can help you with your needs.

If you have questions about data management systems and how to improve your design processes, contact us at Hawk Ridge Systems.

Sources

How to Reduce Non-Value-Added Work in Engineering. Accessed June 2023.

Reduce Wasted Time in CAD Design: Winning the Engineering Productivity Challenge. Accessed June 2023.