3D printing has grown and changed a lot over the years, and through that time there have been common objections that we have seen here at Hawk Ridge Systems that simply are not relevant due to technological improvements over time. In today’s article, we are going to look at five common misconceptions about 3D printing.

1| 3D Printing is Only Good for Prototyping

This is the number one objection that I hear out in the field. And the folks that hold this view can fall into varying levels of objection. On one end of the spectrum, you have those that have totally bought into making functional prototypes with additive manufacturing, but they just can’t see 3D printing being relevant for production or end-use components. And on the other end of the spectrum, you have those who are totally opposed to using 3D printing for any real applications, claiming that printing is only good for trinkets and toys. A lot of feedback that I receive comes from experience with hobbyist-grade equipment. But what about professional additive equipment?

Materials Made for Real World Applications

There have been major improvements to part strength since the early days of additive manufacturing. We now have a wide range of materials from fully printable metals to high-strength composites along with some truly robust plastics. Markforged fits the bill when it comes to offering a wide range of materials that are ready-made for some of the most demanding applications.

High-strength composites bring metal-like strength to plastics printing allowing engineers and designers to create incredibly strong parts right on a desktop-style machine. These composites can meet and even exceed the strength of 6061 aluminum in geometries that are optimized for fiber layouts using a process called continuous fiber reinforcement.

Metal printing capability is also becoming commonplace in manufacturing facilities due to the ability to create complex geometries that can be difficult to produce or costly to outsource. Bringing metal production in-house saves both time and money.

Performance plastics are also becoming more and more prevalent in additive manufacturing with materials such as Ultem 9085 which can withstand some of the harshest environments.

Improvements in Surface Finish & Post-Processing Techniques

The golden combination for additive manufacturing is producing strong functional parts that also look great. This is now possible with improvements both in raw surface finishes and improvements in post-processing techniques. Markforged composite materials such as Onyx have an excellent black matte finish right off the machine. This surface finish can be even further improved through vapor smoothing with AMT equipment.

Raw Onyx with vapor smoothed Onyx enclosures printed with the Markforged X7.

Painting printed parts is also gaining more and more traction in the industry, especially for components that are out in the elements such as car body panels or drone components. Automotive paints and ceramic paints like Cerakote are some of the most common high-quality finishes we see used for production parts off a HP 5200.

Production Printing – Manufacturing End-Use Parts at Scale

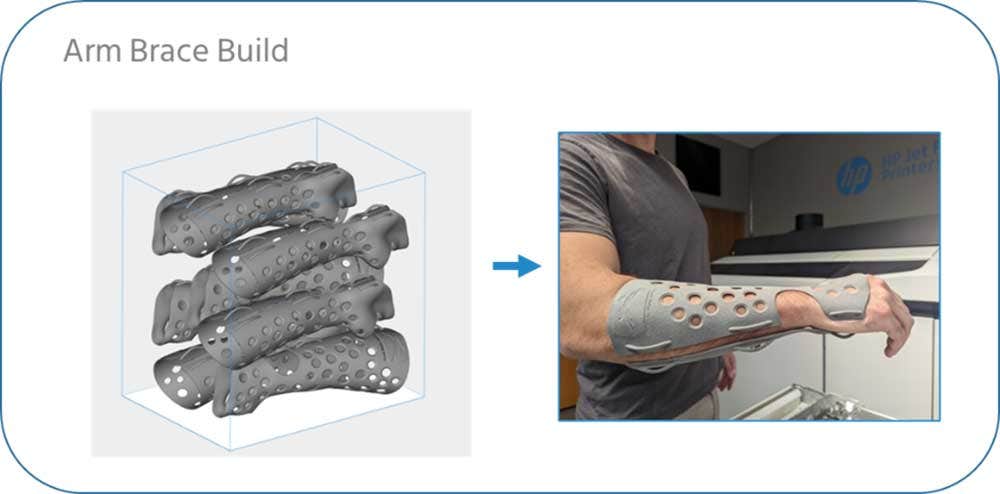

Production printing at scale has been a viable means of manufacturing end-use parts for a few years now. Improvement in speed, reliability, part strength, part cost, and automation opportunities have been key factors in the incredible growth we have seen in this area. Powder bed fusion print technologies such as HP Jet Fusion (MJF) have emerged as front runners to meet the demands of production printing. Companies such as Smiles Direct have been using HP multi-jet fusion to produce dental molds at 50,000 unique parts a day. Customers like MJF because of its ability to compete with injection molding and act as a bridge between prototyping and tooling. Some of our 3D printing Service Bureaus are reporting that customers love being able to prototype and move into full production with one manufacturing process.

2 | We Can’t Afford to Adopt Additive Technology

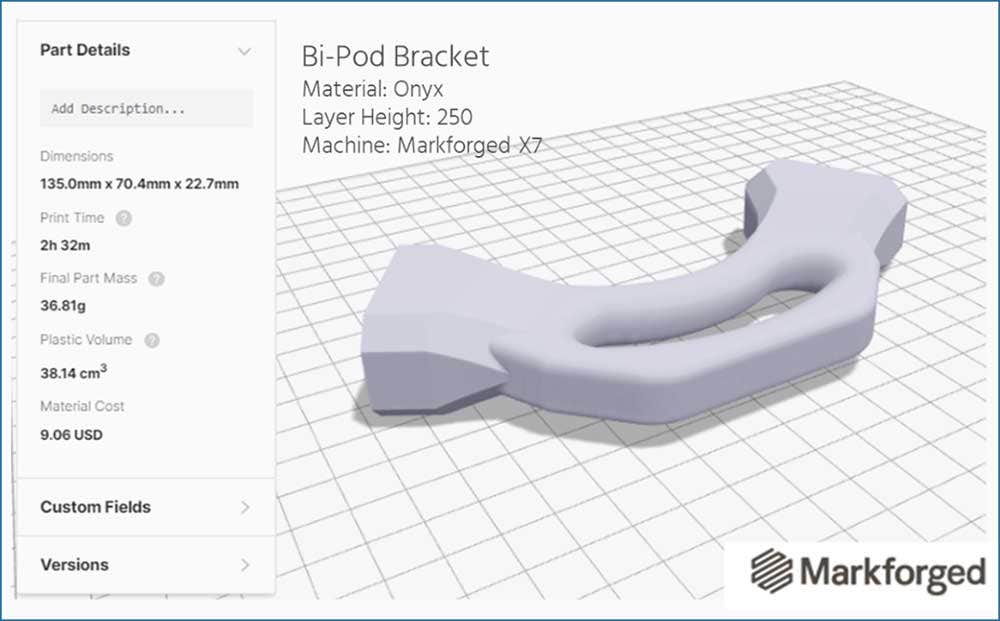

In today’s economic environment of uncertainty, it makes sense to be cautious about where and how you invest capital into your business. When looking at an additive solution it can be difficult to know how equipment can pay for itself. Creating an ROI justification for purchase is key so that you know going in how long it will take to recoup your investment. With tools like the Markforged Eiger Software, calculating part cost and production time is quick and easy. The best part about Eiger is that the software is free to sign up for and use.

With Markforged printing systems, I have seen equipment pay for itself in a matter of a few months. When creating an ROI, it is critical to understand your current costs and time so that you have something to compare against when it comes to an additive solution. Once the justification is there, your next move is to look at your purchasing options such as financing and leases.

Finance Options – Pay as You Go

Nowadays money management is becoming crucial in making smart decisions when bringing additive equipment in-house. A lot of companies are taking a cautious approach towards the end of this year as they reduce risks in large capital investments. As a result, we are seeing a large percentage of our customer base opt for finance options due to low monthly payments which allow companies to make a minimum initial investment and keep capital for a rainy day. There can also be significant tax breaks depending on how you choose to finance the equipment. FMV (Fair Market Value) leases are popular because they allow companies to bring equipment in-house without the debt showing on a balance sheet. This option is a pay-as-you-go scenario using OPEX funds that truly enables companies to allow the machine to pay for itself.

Another style of lease called a Dollar Buyout Lease (Equipment Financing Agreement – EFA) can provide buyers with incredible tax benefits under Section 179 in the first year. This style of lease can often be obtained with zero down payment or payments deferred for up to a year. All these strategies are tried and true and our customers are reaping the benefits. Reach out to us if you would like to try out a finance calculator to determine what your monthly payments might look like for a piece of equipment!

3 | The 3D Printing Process Takes Too Much Time

When adopting any new manufacturing solution, saved time is going to be at the forefront of considerations for a go/no-go. There are key time-saving advantages that can be found in additive manufacturing across both prototyping and production.

Prototyping – Time Savings

Prototyping often involves outsourcing to a machine shop service or placing your job in the queue for an in-house machine shop. This lead time can drag on for a few weeks in many cases whereas an additive solution can complete the task much faster. An in-house printer can often turn parts in a matter of hours without tying up labor resources and printers can run nonstop until the job is done. The Markforged line of composite printers is being used extensively for this purpose. Engineers and designers can support the manufacturing floor without tying up machinists providing high-quality, strong parts at the press of a button. To see how much time you can save with a 3D printed part, be sure and sign up to Eiger to start uploading parts and seeing time and cost numbers for your specific parts!

Production – Time Savings

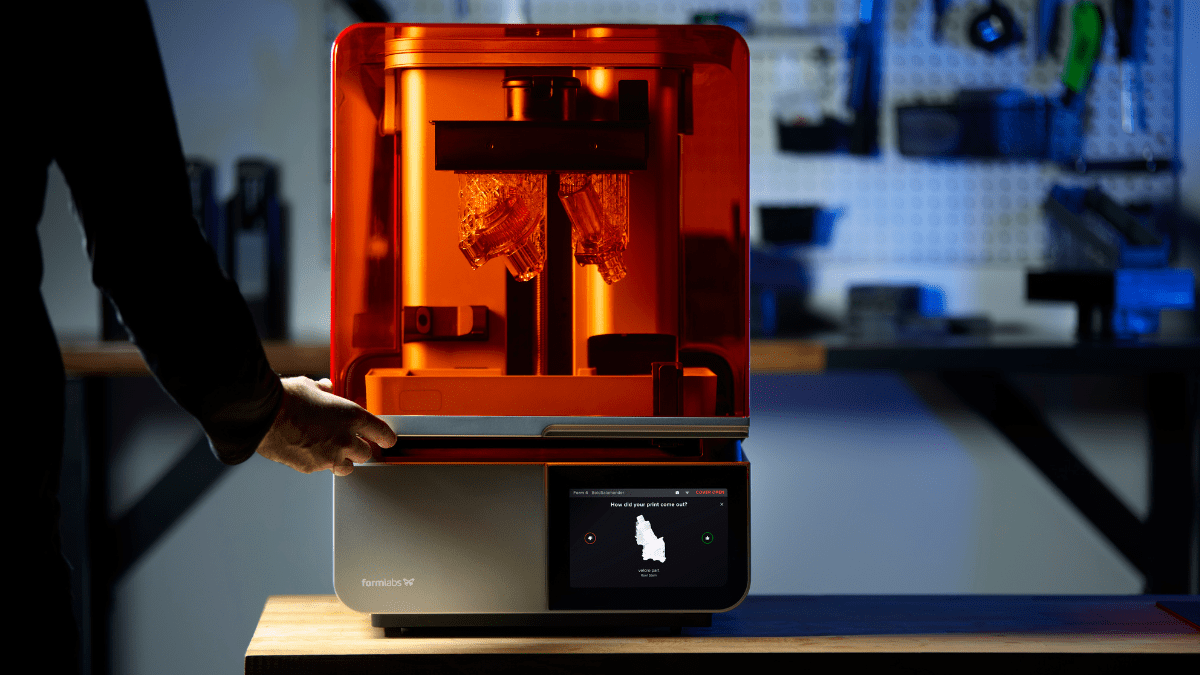

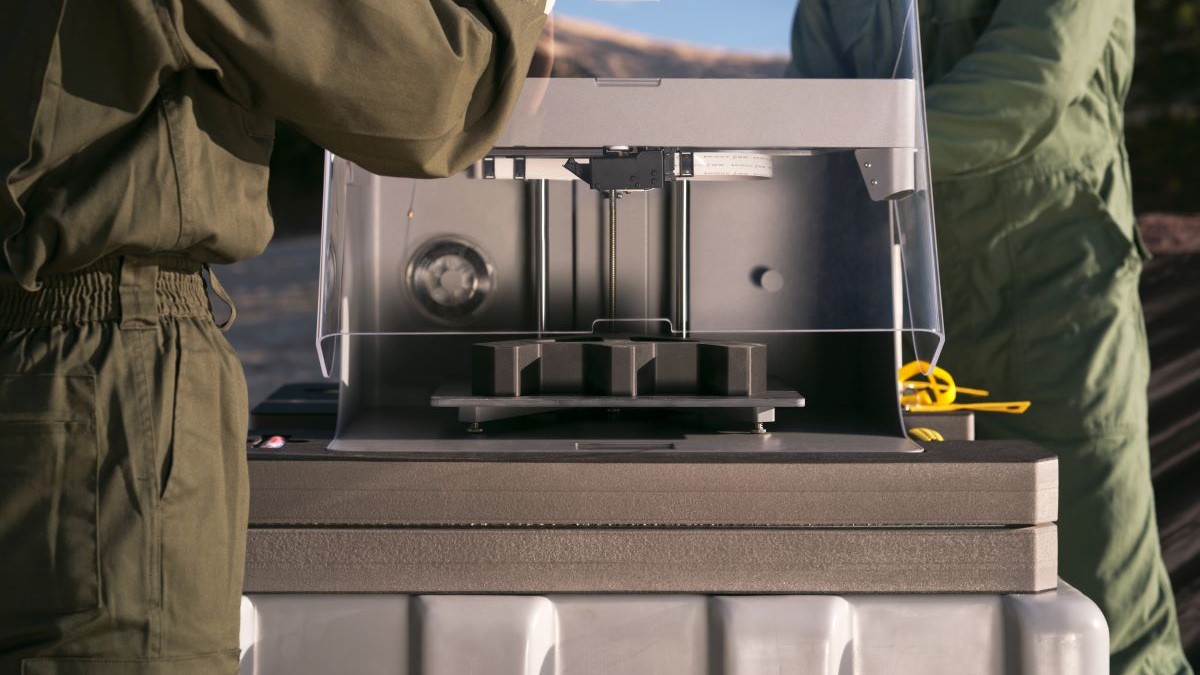

The HP MJF 5200 is a common production printing system on the market today.

With production printing, a design can begin manufacturing immediately rather than having to wait for tooling to be made in a different facility or overseas. Bringing production closer home also saves lost time on costly shipping challenges which can be unpredictable in today’s world. We have had numerous customers come to Hawk Ridge Systems who have battle scars from shipping delays using overseas manufacturing and they are looking to save time and headache by producing parts in-house with an HP Jet Fusion system. With an additive manufacturing solution, re-tooling is not required for design changes and multi-part assemblies can often be simplified due to flexible design freedoms obtained with a printed part. Now you no longer have to wait to start production, you can move to production immediately.

When comparing production printing to CNC machining, a single HP machine can often outpace multiple CNC machines due to the ability to print high quantities of parts simultaneously with complete build volume nesting.

4 | Post-Processing Required Would Be Too Much of a Hassle

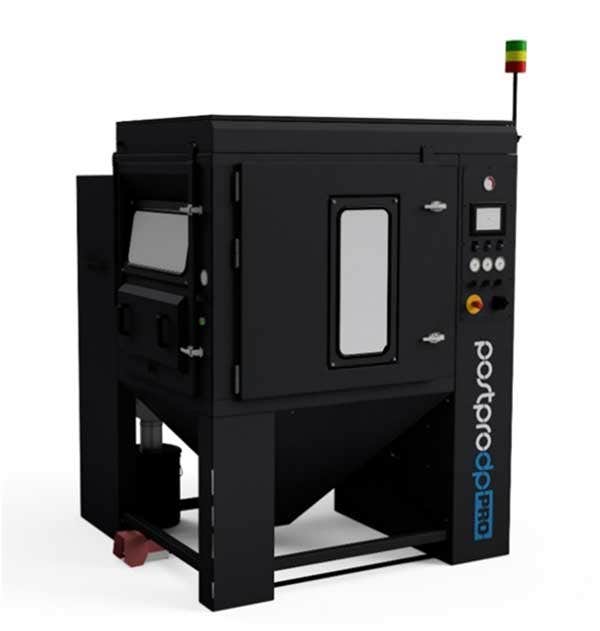

Post processing of 3D printed parts is an area of concern for many, especially those who are looking to produce high volumes of 3D printed parts. With modern production printing systems like HP Jet Fusion, post processing can be automated. With a powder bed fusion system, the last steps after printing and cooling are unpacking and bead blasting. Thankfully, both steps are highly automatable.

Automated bead blasting allows users to simply dump a bucket of parts into a depowdering unit like the AMT DP PRO and then press start for a 15-minute cycle to ready-to-go parts. HP has also gone a step further and developed an automated unpacking station that will recover powder through a vibratory process which saves operators time and labor before bead blasting.

When it comes to post-processing prototype parts from an FFF (fused filament fabrication) system like the Markforged, parts typically take less than a minute to remove support structures for most geometries. These supports can be removed at room temperature by hand or by using hand tools. There also are design strategies that can be implemented to completely eliminate the need for support structures in many cases.

5 | 3D Printing is Difficult to Learn

Additive manufacturing can be seen as complex and difficult to break into, especially for those who have not had much exposure. The good news is that training on additive equipment is typically straightforward and easy. Part of my role at Hawk Ridge Systems is onboarding and training on HP and Markforged printers. With Markforged systems, users can be off the ground in days’ worth of training while the larger production HP systems typically take three to five days. When onboarding with a new printing system with Hawk Ridge Systems we offer onsite, virtual one-on-one training, followed by online resources with each manufacturer. With both Markforged and HP, the onboard user interfaces and intuitive software have gone a long way in taking the guesswork out of printing.

Watch Webinar Now

Want to learn more about these misconceptions in depth? Watch our recent webinar recording!

There you have it; we have looked at 5 common misconceptions about 3D printing. If you have any questions about additive manufacturing for your business, feel free to contact us at Hawk Ridge Systems today!