What Type of 3D Printer is Best for my Business?

3D printing has become a staple for manufactures of all industries. If you are replacing components, creating niche tools to fix a problem in-house, or creating prototypes before production you’ll find there is a printer or material out there for everything. But there isn’t one type of 3D printer that can do it all.

MJF, SLS, SLA, SLS — There are a lot of 3D printer options out there.

With all these options available it can seem overwhelming to find the printer that fits all your needs, and maybe a fool’s errand to narrow it down to one type of 3D printer. Just how one tool can’t do everything for a machine shop efficiency, certain printers can fill roles where others are less efficient.

Instead of narrowing your search to just one type of 3D printer, what if you instead had access to a diversity of 3D printers which help in different scenarios?

In this blog we’ll discuss some of the main types of 3D printing technologies available, where they fit into a production environment, and how companies can benefit from using multiple types of 3D printers to fill different needs.

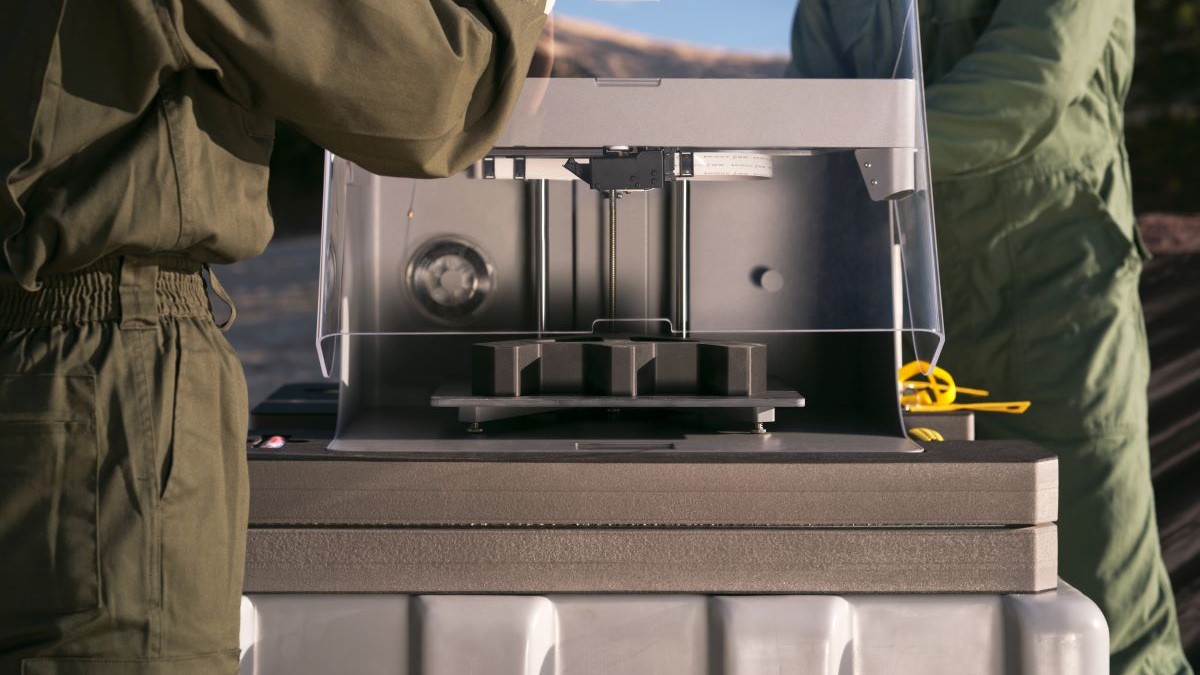

FFF 3D Printers: Fused Filament Fabrication (FFF or FDM printing)

Seen as the most common and affordable method type of printing, thermoplastic is heated to a near-melting temperature and extruded from a nozzle onto a build-plate and follows a defined path programmed by a slicing software. Material is laid layer-by-layer with support material for sections that don’t have layers below or to steep an angle.

This method is used in almost all industries for simple or complex parametric parts that have well-defined features. It’s simple, clean, and can fit into nearly any office with proper space. Since material is laid down one layer at a time, printers like Markforged Mark Two can in-lay continuous carbon fiber to enhance the strength of parts in certain axes based on the orientation printed. Another option is the Markforged FX20 which is better suited for more large format printing.

| Pros | Cons |

|

|

SLS 3D Printers: Selective Laser Sintering (SLS if plastic and DMLS if metal)

This 3D printing method utilizes layers of powder (metal or plastic) laid in a build-volume with a high-powered laser that sinters the powder in select areas to outline the part. As each layer is finished the process is repeated with a new layer of powder added on top of the sintered material. No supports are used to make parts, which saves on material and potential artifacts post-print.

For shapes that have several features and a high-precession tolerance this method is preferred. Large, small, or multiple parts can be produced consistently at once. The parts produced are extremely strong and can be processed further using methods like machining and milling.

SLS 3D printing machines are typically very large, meaning bigger build-volumes for parts as well. The Formlabs SLS 3D printer is an example of an SLS printer that can create complex geometries and functional parts with a lot of strength and smooth finishes.

| Pros | Cons |

|

|

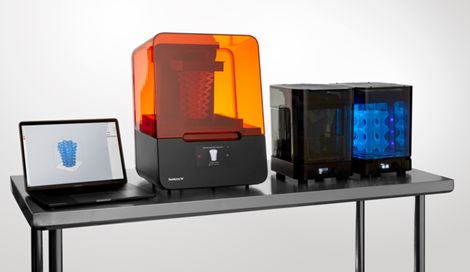

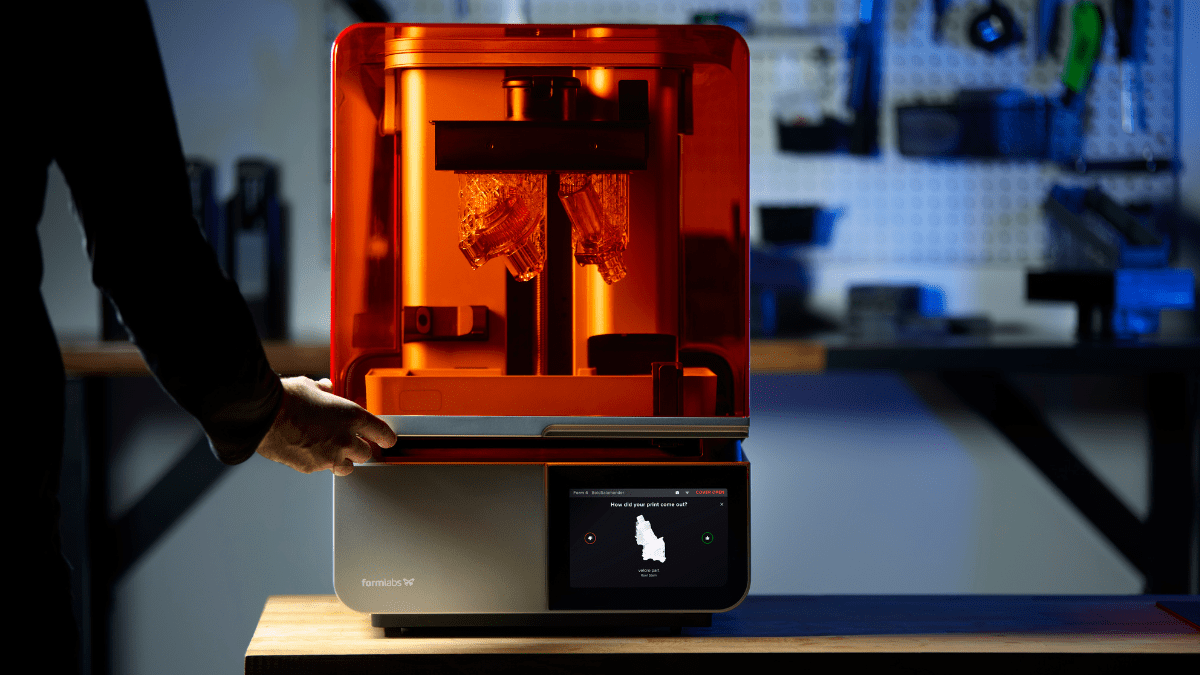

SLA 3D Printers: Stereolithography (SLA)

A light-cured method to create smooth and complex-shaped parts out of photopolymer material. A printing bed is dipped into a pool of resin and a light quickly cures the material onto the bed in select areas. As each layer is finished the bed is slightly raised for the next layer. While complex shapes are possible, you may need supports to hold parts in place as the print is raised from the resin. Once a part is finished being printed it is washed to remove wet resin and, for some material, re-cured to achieve full-strength.

SLA 3D printing is widely used for molds, prototyping, and smaller end-use parts where material finish needs to be smooth. By using a resin base for material, certain properties can be achieved like clear-elastic or wax as seen with Formlabs printers that use SLA technology like the Formlabs SLA 3D printer. These printers can be smaller in size, making them a great fit for offices instead of production floors. Many companies utilize a fleet of them for faster production.

| Pros | Cons |

|

|

Binder Jetting 3D Printers (or Multi-Jet Fusion for HP)

Similar to SLS, binder jetting 3D printers like the Multi-Jet Fusion HP, print by applying a layer of powdered material onto a build volume. Then a print-head sweeps across to inject binding liquid in specific areas based on the part. As each layer finishes, the build volume lowers and more material is layered on top. Then the process repeats.

HP printers will use a second sweeping bar to cure the binder after each layer, while other printers may need curing or sintering after the part completes. This process doesn’t use any supports to create parts and can even embed parts into each other to maximize the build-volume or minimize assembly post-printing.

Binder jetting is a cost-effect and low energy method of producing parts compared to SLA. With binder jetting you can produce multiple types of parts at once or create a higher volume of parts by nesting them together. The Multi-Jet Fusion printer is one of the fastest 3D printers for additive manufactures that want to produce strong parts with fine details at scale.

| Pros | Cons |

|

|

Why You Should Diversify Your Setup with Multiple 3D Printing Options

As you can see these different printing methods have some overlap, but all have different requirements for post-processing, material specifications, and energy needs.

The top reasons for designers, manufacturers, and specialists to use different types of 3D printing involve having a wider selection of material options and shapes, creating prototypes faster, and even meeting regulatory requirements.

Total possibilities for materials

Having access to a wide selection of 3D printing materials ensures you’re able to produce any part internal or external that is needed. And different materials will be needed depending on regulations and needs for strength, flexibility, and reliability.

For example, Formlabs SLA printers, using layered resin, allow for a completely different diversity of material applications as opposed to Markforged’s FFF printers which are based on nylon and carbon fiber layering.

Total possibilities for shapes

A 3D printed parts strength and end-look is driven by their printing orientation and method of production. Assembly may not even be possible without the use of nesting or removable supports as well. If you are looking to cover all bases in your ability to print a part, having a mixture of surface-finish, nesting, and layering printers ensures you have the right tool for what you’re looking to produce.

Prototype vs. production for cost and time efficiency

Just as you wouldn’t use your highest-throughput machine to test-run a part, you don’t want to slow 3D printing production down to print a few prototypes. FFF and SLA printers are known for their low heat and fume exhaust, allowing them to be placed in offices to run prototypes before using larger printers for production runs.

Confidence and certification

Certain printers are certified for regulatory and industrial needs, such as the Markforged’s FX20 use of ULTEM™ 9085 Filament material, Formlabs 3B for dental, and HP’s 5420W for white medical material. If you want to ensure you adhere to regulations but still want to prototype parts, having a mixture of 3D printers allows you to specify their use, making production easier to scale.

Industrial Use-cases for Mixed 3D Printing Production to Improve Operational Efficiency

By having a mix of 3D printers at your hands, you can improve operational efficiency and also reduce outsourcing costs. Here are some common use-cases for why you would want to have a mix of different 3D Printers available:

Use-case: Metal 3D Printed Parts with and associated soft jaws

Metal 3D printing creates lighter and more customized parts than traditional manufacturing methods. But if you want to machine these parts to tolerance, you’ll need a fixture just as unique. You could simply order it, but it will likely be expensive, and it may take a long time to ship. Instead, you could take the entire process in-house by using an additional printer like Markforged, which is used for soft-jaw products. With multiple types of 3D printer options, you can produce both metal and soft jaws simultaneously without the lead time. And by having both in-house, the soft jaws can be rapidly prototyped for proper fit before printing the actual fixture.

Use-case: Printing Molds and High-Temp Fixtures

Are you rapidly prototyping molds and having to outsource not only the mold but the fixture that holds it? Both have vastly different requirements for material and surface quality, which may be difficult to make off a single printer. Despite that, the cost-savings of having two printers that specialize in each aspect can be faster and cheaper than having to outsource the process.

Use-case: Print Prototypes and Low-Cycle Parts Before Using Production Tools

One of the more popular uses for using an office printer and production floor one is to validate parts for shape and feel using lower-cost material before moving to production floor for mass-printing with regulated material. This combination allows total control over when and how parts are printed so research and design can continue without interrupting throughput of product. When a part is validated, teams can simply upload the file to the new printer to begin production.

Learn More About Diversifying Your 3D Printing Setup

It’s difficult to predict what issues may arise in manufacturing or what areas a 3D printer may be useful for your environment. By diversifying your 3D printers, through strategic selection based on material, use-case, and time-efficiency, you can prepare to work around anything that may come your way in the additive manufacturing world.

Want to learn more about the types of 3D printer technology available? Contact us today to speak with an expert!