Learn how Computational Fluid Dynamics (CFD) enables virtual prototyping across life sciences including medical, pharmaceutical, and biotechnology in this blog article and recorded webinar. We’ll discuss a variety of applications including optimization of a microfluidics circuit, analysis of an inhaled drug delivery device, and passive cooling of electronics in a medical environment.

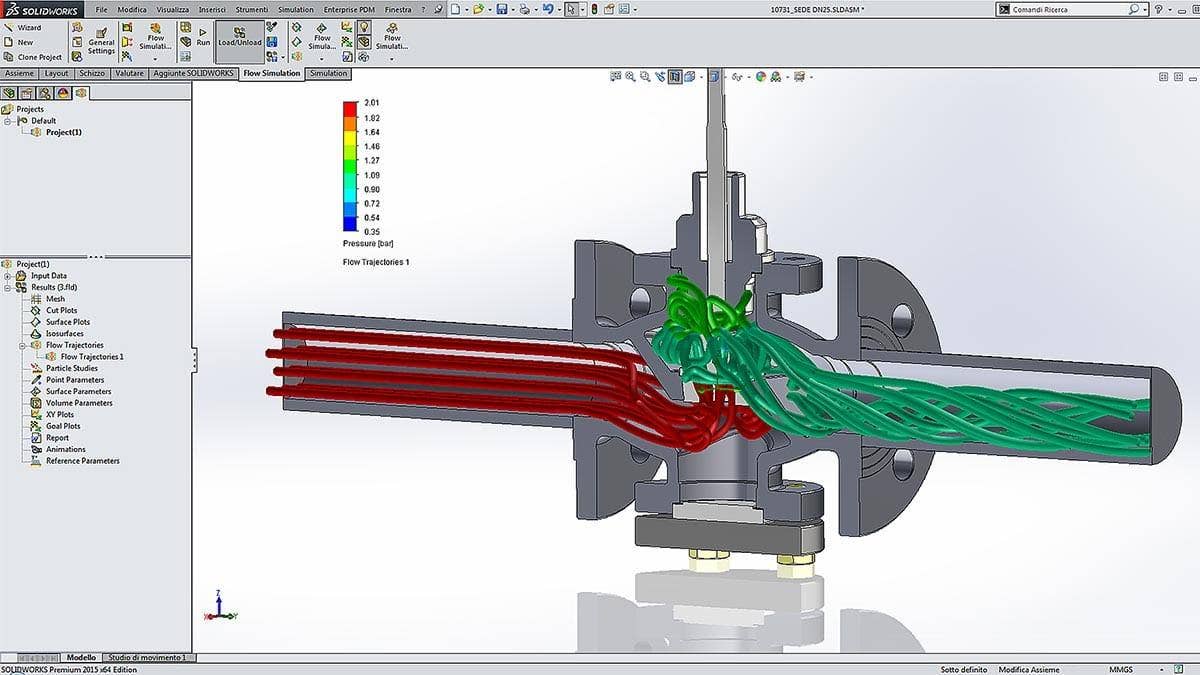

We’ll show how rapid iteration is possible with very little training in the CAD-embedded SOLIDWORKS Flow Simulation, and also examine more advanced use cases made possible by tools within the SIMULIA product line.

Microfluidics and Fluid Mixing

Pharmaceutical and biotech researchers often rely on a “lab on a chip” to process samples and cultures. These devices often feature fluid passageways on the order of micrometers, and the design and analysis of fluid behavior at this scale is referred to as microfluidics. Devices designed at a slightly larger scale may be referred to as millifluidics.

Fluidic circuits designed with this approach can accomplish various behaviors, but the example below depicts mixing fluid from multiple sources to a desired concentration.

Computational Fluid Dynamics tools such as SOLIDWORKS Flow Simulation allow definition of multiple fluid sources for prediction of mixing behavior through the device. Particles can also be injected into the fluid flow and parameters such as their travel distance and residence time can be calculated.

Tesla Valve

To achieve a check valve-like behavior in fluidic devices the Tesla valve design is very useful as it features no moving parts! Originally patented by Nikola Tesla in 1920, the design has seen a resurgence in popularity with applications in modern microfluidic devices.

A key design parameter for the Tesla valve is the “diodicity” or ratio of the pressure drops in the reverse and forward directions, for a given flow rate. Using CFD allows optimization of valve geometry to maximize the diodicity, which may vary situationally depending on the fluid velocity and any dynamic effects (such as a pulsing or pulsatile flow).

Drug Delivery and Treatments

Drug delivery devices and applicators can also benefit from a multi-fluid mixing simulation. In the case of an inhaler, there is a mixture of propellant, drug, and ambient air which can all be represented simultaneously in a simulation to achieve target drug concentrations at the outlet. Thermal effects can also be explored for drugs that must be temperature controlled.

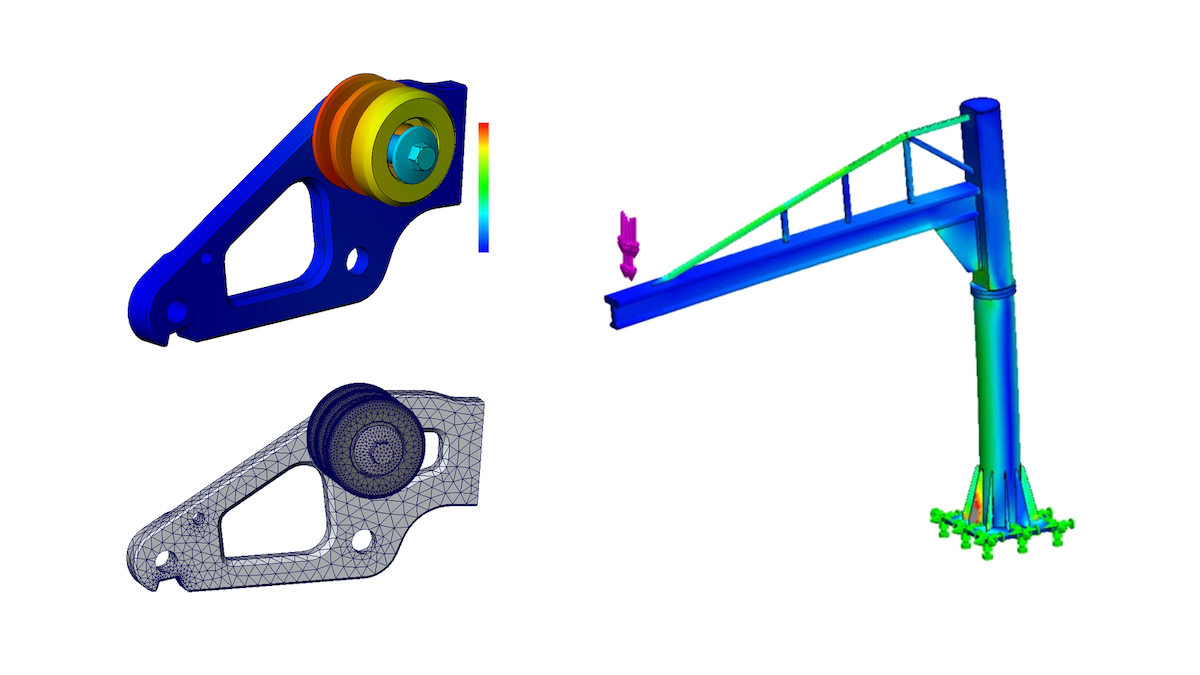

For intra-venous or subcutaneous injected drugs, CFD may be used alone or in conjunction with Finite Element Analysis (FEA) if detailed modeling of a syringe or pump is required.

Thermal Management

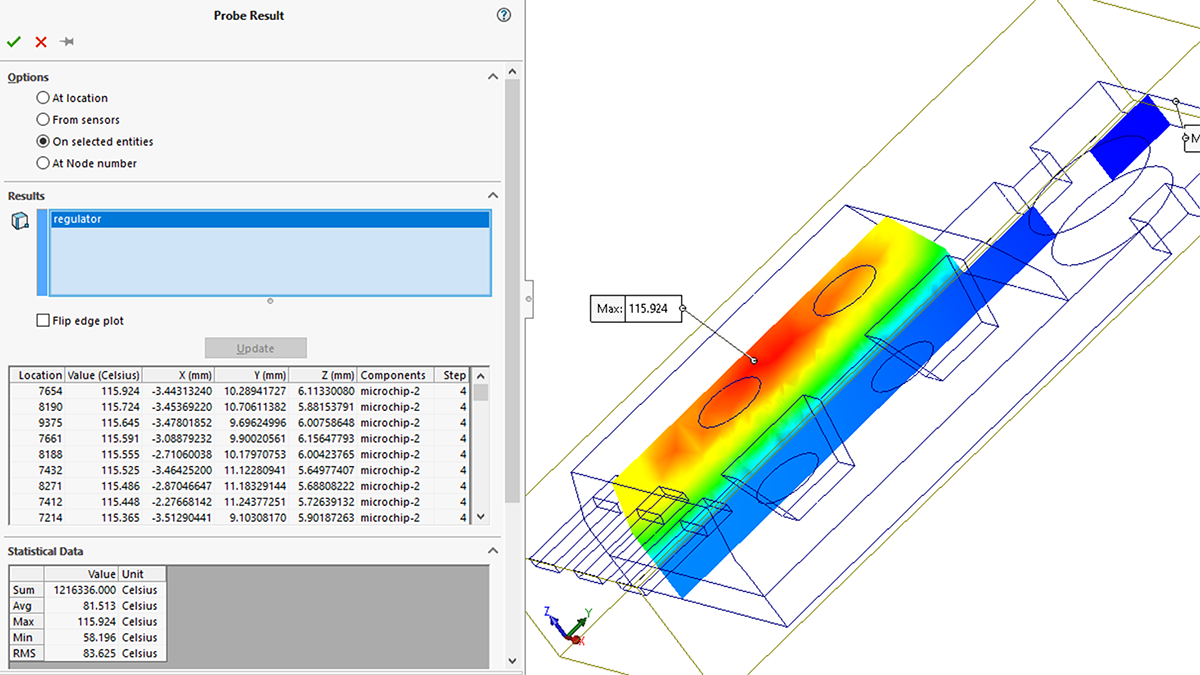

With the rise of connected medical devices, electronics cooling simulation has become an important part of many medical device product design cycles. In a medical environment, to avoid kicking up dust and reduce risk of contamination, it may be desirable to have a hermetically sealed enclosure which dissipates heat only through natural convection.

SOLIDWORKS Flow Simulation makes this sort of analysis very straightforward. The main setup only requires you to define the device orientation with gravity direction and any relevant heat sources and solid materials. The CFD simulation takes care of the rest, combining the effects of fluid dynamics and conjugate heat transfer to represent the natural convection process.

To learn more about these applications and more, check out the recorded webinar below!

Frequently Asked Questions

1. Where are microfluidic devices used?

A common application is a “lab on a chip” for processing cell cultures, assays, and other biological applications. The very small volumes used allows processing of many samples from a limited amount of input. The ability to design “circuits” of fluid allows for complex behaviors.

limited amount of input. The ability to design “circuits” of fluid allows for complex behaviors.

Outside of life sciences applications, microfluidic devices are also used for inkjet printers.

2. How are microfluidic devices manufactured?

Microfluidic devices may be constructed by a CNC micro mill or chemical etching / photolithography. At the slightly larger millifluidic scale, they can even be 3D printed with new sterilizable polymers like the Formlabs Biomed Clear Resin.

3. What are the differences between microfluidics and fluid dynamics at traditional scales, and how do they impact simulation approaches?

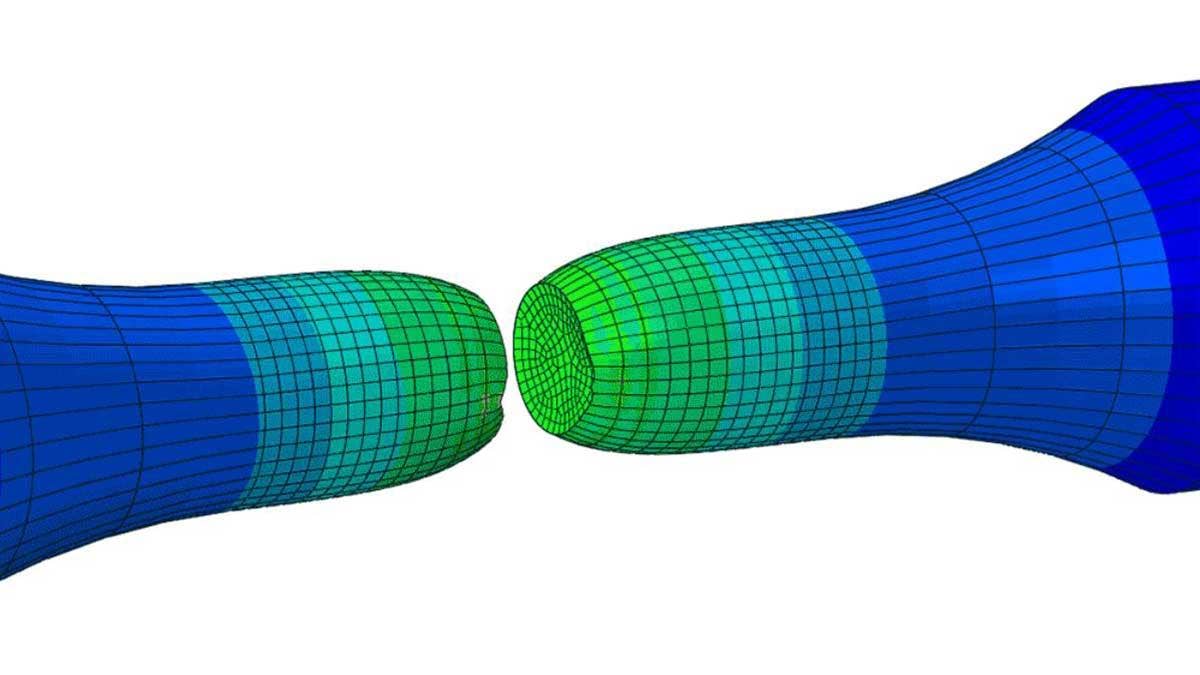

Compared to fluid dynamics at traditional scales, liquid flow in microfluidics is almost always laminar, so problems involving the mixing of two fluids (which traditionally would benefit from turbulence) may require a different approach, including long snaking channels.

At microfluidic scale, physical effects that are normally ignored at larger scales (such as the surface tension or capillary action of liquids) may become an important factor. At small enough scales (on the low end of microfluidic scale) the slip length of a liquid may become a significant contributor to the overall flow pattern, meaning the traditional “no-slip” wall condition may not be a safe assumption.

For particles suspended in the fluid, additional forces may need to be considered at very small scales.

4. How does mesh resolution affect the accuracy of Fluid flow simulations?

Particularly for multi-fluid mixing problems, it’s important to have high mesh refinement to minimize the “numerical diffusion” that occurs when the mesh settings are too coarse. Numerical diffusion will cause the simulation to have a greater than expected mixing performance due to averaging errors in the simulation.

5. How does SOLIDWORKS Flow Simulation compare to other tools in terms of handling special cases like surface tension and capillary action?

SOLIDWORKS Flow Simulation can be great for millifluidics and larger scale microfluidic applications as a “first pass” simulation tool for making design-time decisions, but it doesn’t have any capabilities around surface tension or capillary action.

For problems involving these additional physics that may need to be represented at smaller scales, we have additional fluid simulation tools available from SIMULIA.

6. Why is the Tesla valve often used in microfluidics applications?

The biggest benefit of the Tesla valve design is it features no moving parts and can be cut into channels with whatever existing manufacturing process is planned for the microfluidic device.

It’s worth noting that Tesla valves don’t generally rely on any special effects that come into play at micro-scales, and function just as well at large scales too. We just don’t see them used at large scales as much since traditional check valves are readily available and affordable. Unlike a traditional check valve, the Tesla valve will always feature some leakage.

Tesla valves may also feature much greater durability in situations where flow reversal is especially frequent or violent.

7. Can you explain the concept of diodicity and its importance?

The key performance characteristic of the Tesla valve is its “diodicity”, which can be defined as the ratio of the flow rate in the forward flow direction, over the reversed flow direction for a given applied pressure.

8. How does fluid simulation help the design of drug delivery devices?

One of the biggest benefits of upfront fluid simulation is to first predict the feasibility of achieving desired drug concentrations and flow rates for design concepts. Multiple species of fluid can be defined, and their mixing behavior calculated directly.

Later on the simulations can be used to fine tune things like the uniformity of concentrations or velocity using optimization methods available in Parametric Studies, which are built-in Design of Experiments tools for batch iteration.

If there is any aspect of the process that is temperature controlled, thermal effects can be combined simultaneously with the analyses outlined above.

9. What are the advantages of using cloud solving and cloud results sharing for fluid simulations?

In general, cloud solving provides the capacity for additional iteration and experimentation without having to dedicate a powerful workstation or tie up the engineer’s main PC.

Cloud results sharing can enable key stakeholders within the organization to directly access and interpret simulation results, rather than requiring the CFD user to generate and share reports or screenshots.

10. How does fluid simulation help with thermal management?

Many problems may involve thermal management, such as regulating the temperature of a drug or other fluid during processing or attempting to cool electronics or other devices. In either case, CFD is a very useful tool since it allows simulating thermal and fluid effects simultaneously.

For passively cooled electronic devices for instance, all that’s really required is defining the heat sources, solid material properties, and gravity direction – the solver then takes care of the conjugate heat transfer between the solids and surrounding air with the heated air rising and cooler air filling in to take its place forming currents of natural convection.

Getting Started with Fluid Simulation for Medical and Biotech

Check out the full webinar to learn more about medical and biotech with fluid simulation tools like SOLIDWORKS Flow Simulation and Simulia.